Table of Contents

Beams are structural members that transfer the load on the structure to the column that in turn transfers the load to the ground. The beam resists external load and the primary deflection of the beam is by bending. The beam is a horizontal member and a flexural member.

Beams resist applied load by producing reaction forces at the support of the beams. The loads and external forces acting on the beam produces shear forces and bending moment in the beam that induce stress, strain, bending moment within the beam, and deflection of the beam.

There are different types of beams such as simply supported beam, fixed beam, cantilever beam, truss beam, overhanging beams, etc.

The load applied on the slab of a building is uniformly transferred to the column with the help of beams. Thus beam helps in distributing the load on the structure uniformly. Beams are the intermediate structure that helps in transferring the load through the column and foundation to the ground.

Types of Beams in Construction

Different types of beams and their classification is based on the basis of the type of support, the cross-section of the beam, material, geometry, equilibrium, and the method of construction of the beam.

Classification of the beam is shown below:

- Beam based on Loads and Supports

- Simply Supported Beams

- Fixed Beams

- Over Hanging Beams

- Double Overhanging Beams

- Continuous Beams

- Cantilever Beams

- Trussed Beams

- Girdle Beams

- Beams based on Geometry

- Straight Beams

- Curved Beams

- Tapered Beams

- Deep Beams

- Beams based on Equilibrium Conditions

- Statically Determinate Beams

- Statically Indeterminate Beams

- Beams based on Material

- Reinforced Concrete Beams

- Steel Beams

- Timber Beams

- Composite Beams

- Beams based on Cross-Sectional Shape

- Rectangular Beams

- I Beams

- T Beams

- L Beams

- C Beams

- Square Beams

- Beams based on Construction Methods

- Cast in-situ Concrete Beams

- Precast Concrete Beams

- Prestressed Concrete Beams

- Lintel Beams

Purpose of Beams

The primary purpose of the beam is to transfer the load on the structure efficiently to the column and foundation. Other than load transfer beam structures are also used for the following purpose:

- Balancing the shear forces and bending moment developed inside the beams.

- Resist the load that is applied to the structure.

- The beam distributes the load uniformly to the column.

- Beams bind the structure together so that the structure is united all the time.

Reinforcement in beams

To fulfill the above purpose of the beam, it needs to be reinforced with reinforcement of different types. Some of the commonly used reinforcement in beams are mentioned below:

- Main Bars: These bars are provided to take the load of the structure and counter the shear force and bending moment. The main bar is generally provided at the bottom of the beam.

- Support Bars: To hold the beam reinforcement that is main bars and stirrups in place certain bars are provided at the top of the beam, this is called support bars.

- Stirrups: To hold main bars and counter the shear forces or shear stress in beams stirrups are provided at certain intervals in vertical position.

Related: Complete Reinforcement Details For Column, Beams, And Slab

Beam based on Loads and Supports

Beams can be classified according to the type of support or load acting on the beam. The end support of the beam can be fixed or free. If both ends are fixed then it is simply a supported beam and if one end is free then it is a cantilever beam.

All different types of beams that can be classified on the basis of loads and supports are shown below.

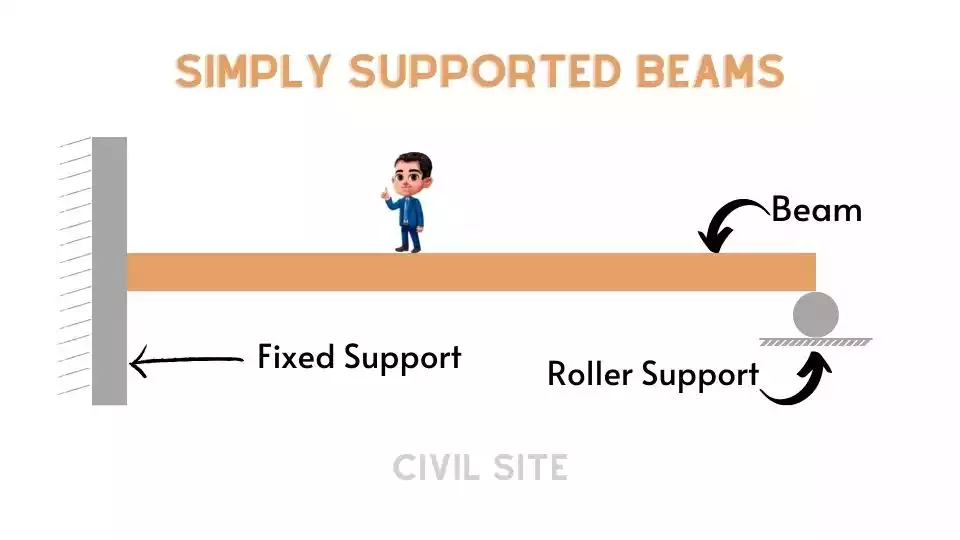

Simply Supported Beams

In simply supported beams both ends is supported by hinge or roller support. Roller support in simply supported beams helps the horizontal movement of the beam. Shear stress and bending moment are induced in this type of beam.

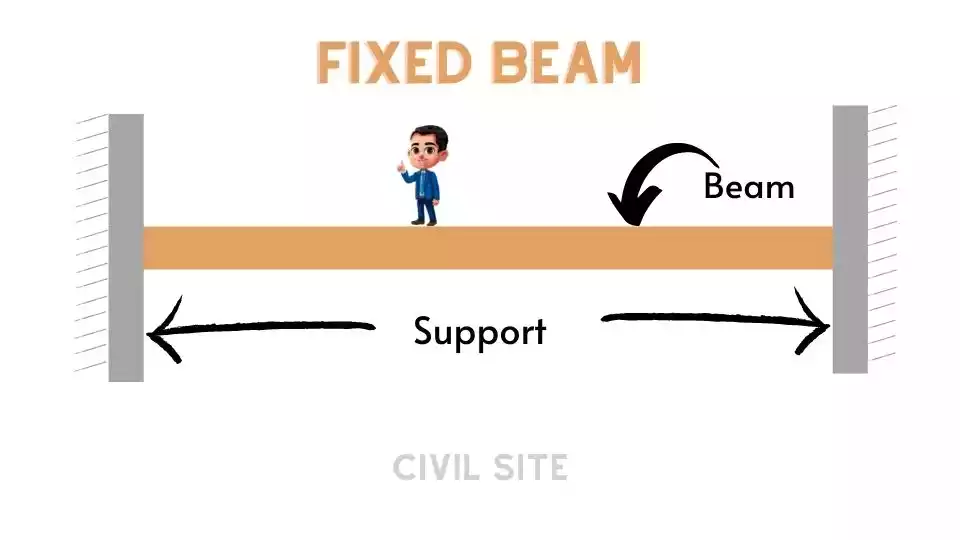

Fixed Beams

If the end support is fixed then this type of beam is called a fixed beam. Horizontal, vertical and rotation of the beam are restricted in this type of beam. Fixed beams are used in trusses and other types of structures.

Both ends of the beam are fixed with reinforcement to restrict end rotation and tilting movement of the beams. In residential buildings and high-rise buildings, all beams are fixed beams.

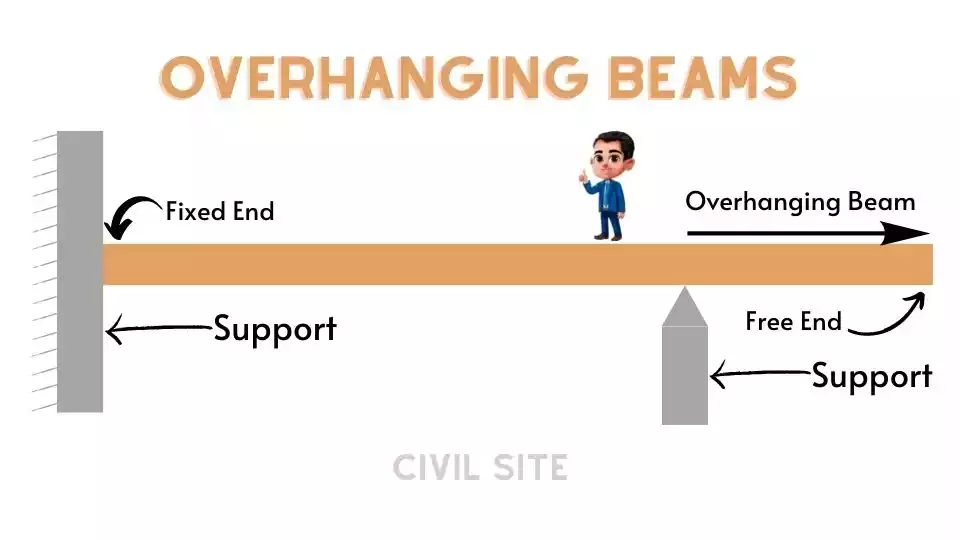

Over Hanging Beams

In overhanging beams, one end of the beam is fixed and the other end extend outside the column up to some distance. The protrusion of the beam can extend from 40 cm to 120 cm in general.

The overhanging beam is similar to a simply supported beam, the only exclusion is that one end of the beam extends out of the column. In residential buildings, the overhanging beam is used for making balconies and shades.

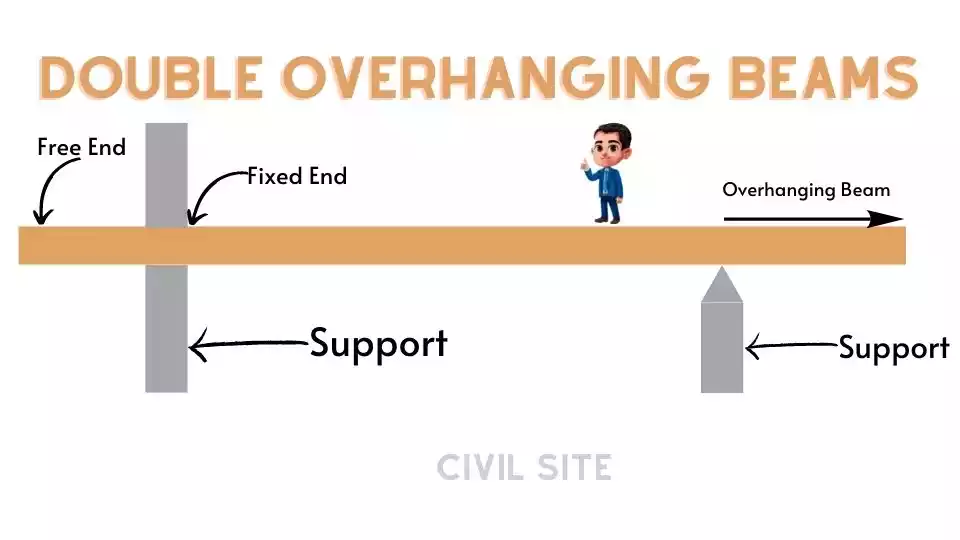

Double Overhanging Beams

As the name suggests double overhang beam is similar to overhanging beam but it has an overhang on both sides of the beam. If the beam is fixed in between but the ends of the beam is free to rotate then it is called a double overhang beam.

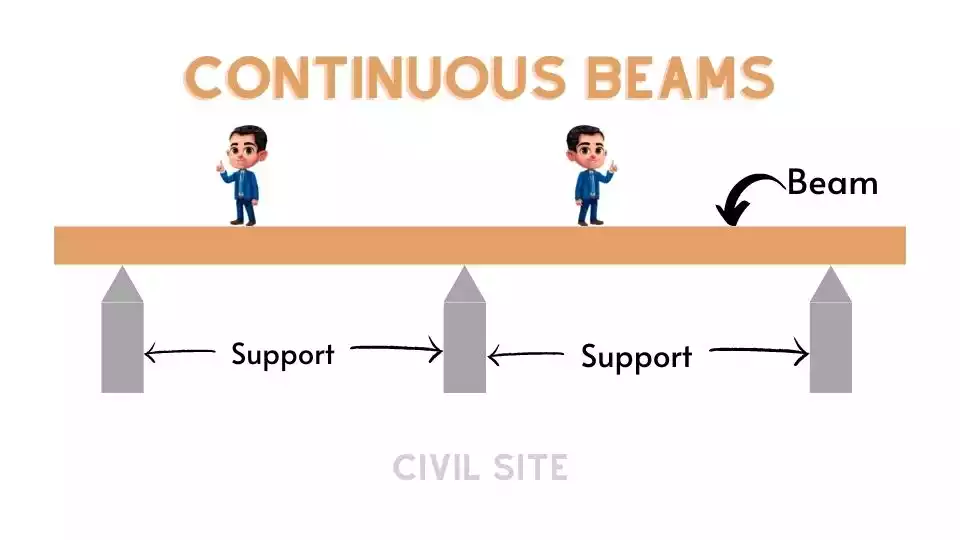

Continuous Beams

In a continuous beam, there is more than one span with more than two supports. The beam is called a continuous beam if the beam has intermediate support other than the end supports.

It is like more than one simply supported beam joined together to form a continuous beam like structure. An example of a continuous beam can be seen in the case of bridge construction, A continuous beam has more than 2 supports along the length of the beam.

One of the advantages of continuous beam is that it has lesser maximum deflection and lesser maximum positive bending moment as compared to simply supported beams.

With continuous beams, we can have a larger span of the beam in comparison with simply supported beams.

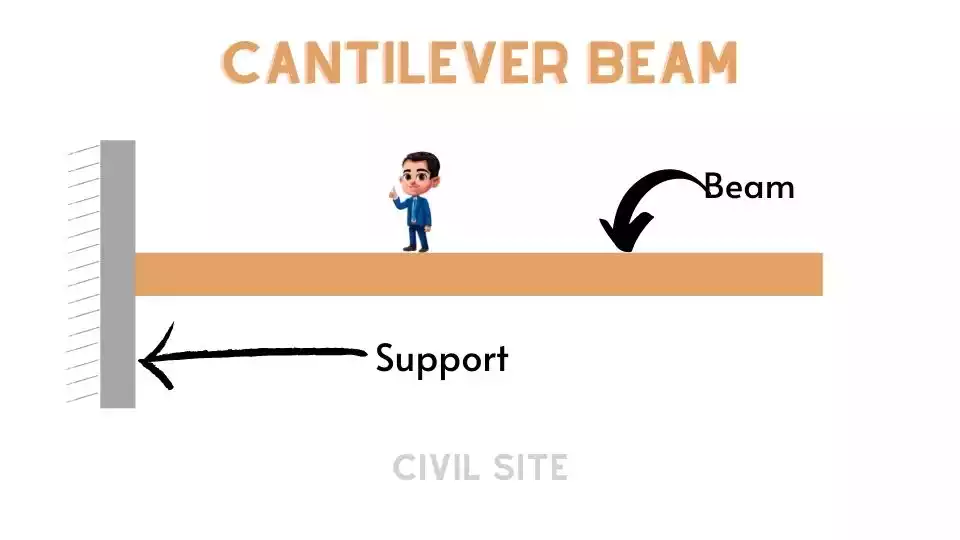

Cantilever Beams

In cantilever beams, one end of the beam is fixed and the other end of the beam is free to rotate. Support in the case of a cantilever is only provided at one end of the beam and another end is free to rest.

Cantilever beams are provided in the car parking area, bridge construction, towers, etc. The load exerted upon the beam is transferred to the fixed support and it provides equal and opposite reactions to the force applied on the beam.

Moment and shear stress induced in the cantilever beam on the free end is managed by the fixed support of cantilever.

Trussed Beams

When there is a need for a long span and the continuous beam can not be provided then the beam can be reinforced with a truss to take the load. This type of beam is called a trussed beam.

The trussed beam is mostly used in warehouse sheds, workshop sheds to take care of longer spans and open space requirements.

Beams based on Geometry

Based on the geometry of the beam, it can be classified as straight beams, curved beams, tapered beams and deep beams. The geometry of the beam is important in mechanically resisting loads that can come on the structure. Details information on each of the beams type is shown below.

Straight Beams

Beams that have straight profile throughout the length of the structure is called straight beams. This type of beam is very common and mostly seen in residential buildings.

Straight beams are typical beams supported at the ends and can resist shear forces and bending moments. This type of beam is comparatively easier to construct.

Curved Beams

Beams that are not straight but have a curved shape or profile in the elevation of the beam are called as curved beams. Curved beams are used in building or structure that has circular or curved shape.

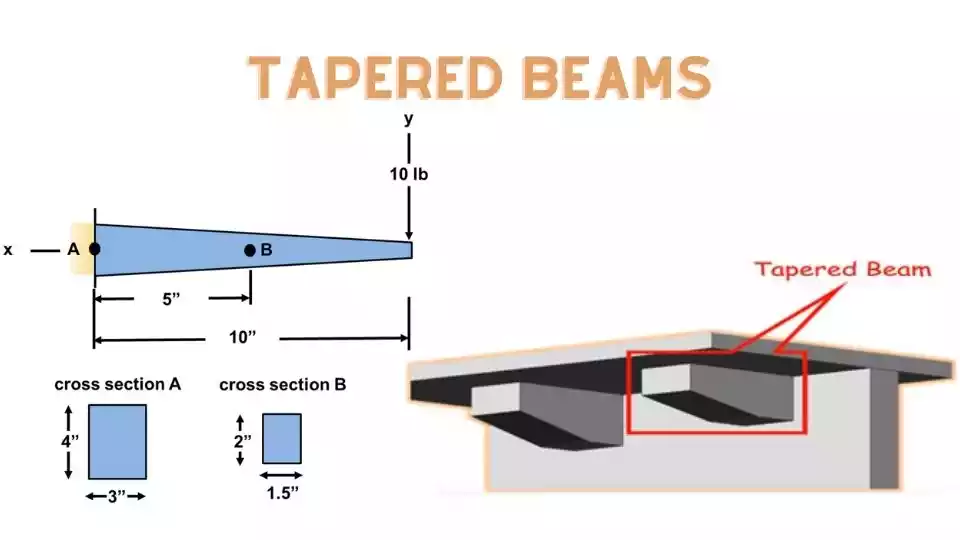

Tapered Beams

If the end of the beam is not of uniform shape and has varying depth then it is called a tapered beam. The tapered beam has a tapered shape as shown in the above figure.

A tapered beam is a non-prismatic beam of varying depth or width at its ends or mid-span. It is widely used in construction due to its high stiffness-to-mass ratio. It has better shear carrying capacity when compared with prismatic beams.

Tapered beams have higher lateral stability than uniform beams and also help in reducing the dead load of the beam and saving weight

Recommended For You:

- Standard Door Size

- Standard Kitchen Size And Dimensions

- Standard Size Of Column

- Standard Height of Plumbing Fixtures

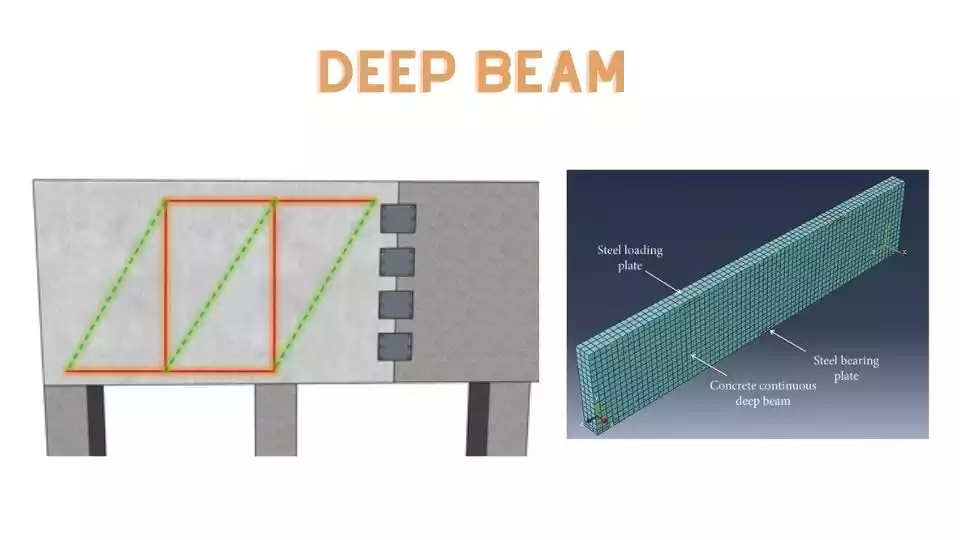

Deep Beams

The depth of beams in certain case need to be increased to withstand bending moment of higher magnitude, occurring due to longer span and high magnitude of loads.

Deep beams have a high depth-to-thickness ratio and shear span depth ratio of less than 2.5 for concentrated loads and less than 5 for distributed loads.

Example of deep beams is short-span beams carrying heavy loads, floor slab under horizontal load, and transfer girders.

Beams based on Cross-Sectional Shape

Beams can also be classified according to the cross-sectional shape of the beam. Below we have shown beams based on the cross-sectional shape of the beam with images.

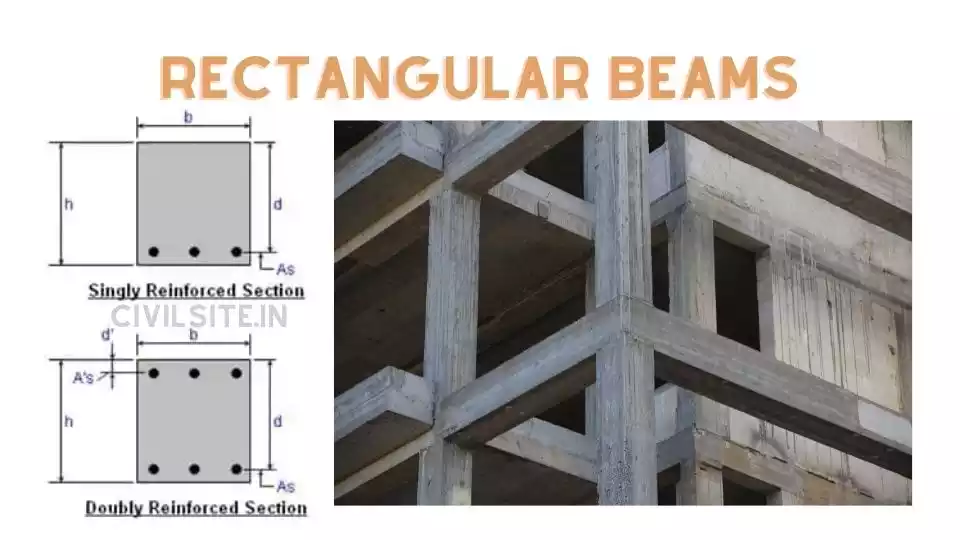

Rectangular Beams

A beam having a rectangular cross-sectional shape is known as a rectangular beam. Rectangular beams experience tension at the bottom and compression at the top. Hence to counter tension at the bottom more steel reinforcement is provided at bottom of the beam than at the top of the beam.

Rectangular beams are widely used in construction from small houses to high-rise buildings.

I Beams

I beams resemble the shape of the English letter I. Thus the name of this beam is termed as “I beam”. I beams are structural members with a central web and crossbar or flanges at the bottom and top of the beam.

Mostly I beam is made of steel but it can also be made of concrete or fiberglass. This type of beam is mostly used in the construction of manufacturing plants and multi-story buildings.

I beam are popular as they resist bending, vibration, deflection, and yielding due to their shape. I beam are also called H beam or universal beams or rolled joist.

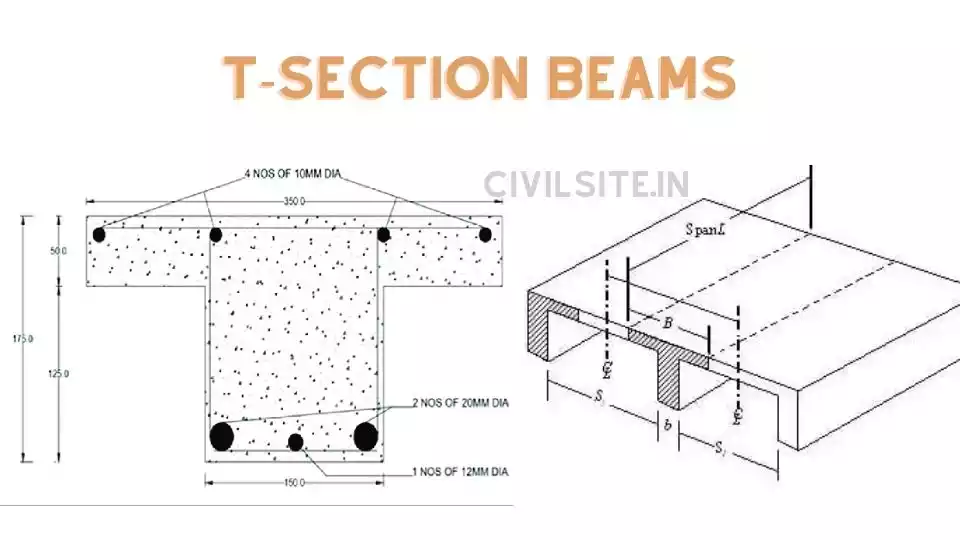

T Beams

Tee Beam or T beam has a cross-sectional shape similar to the English alphabet T. It is cast monolithically with the slab. Due to the monolithically casting of the beam with the slab, the slab becomes an integral part of the beam.

The slab is called the flange for the T beam and the beam portion below the flange is called the web. T beam can have a larger span of the beam compared to the rectangular beam as the deflection of the beam is greatly reduced.

L Beams

L beams are a structural element used in the case of small loads or supporting components of larger loads. The image of L beam is shown above.

L beams are compact beams that resemble the English alphabet “L” hence it is named L beam. L beam can support a heavier load in comparison to the flat beam.

L beams are also called angle beams. L beam has two legs that are joined at a right angle forming an L shape.

C Beams

A beam in the shape of a channel section resembling the English alphabet C is called a C beam. C beam is commonly known as channel section or C section. The image of C beam is shown above.

Square Beams

Square beams are similar to rectangular beams only difference being its width and depth are equal. An image of a square beam can be seen above.

Beams based on Equilibrium Conditions

If basic equilibrium conditions are enough to analyse a beam then it is called a determinate beam otherwise statically indeterminate beam. Based on the above we can classify beams into two types, that is statically determinate beams and statically indeterminate beams. In detailed classification is shown below.

Equilibrium conditions are

- The summation of all horizontal forces is equal to zero,

- The summation of all vertical forces is equal to zero, and

- The summation of all moments is equal to zero.

Statically Determinate Beams

If the equilibrium conditions are satisfied and enough t analyse a beam then this type of beam is called a statically determinate beam.

Examples of statically determinate beams are cantilever beams, simply supported beams, etc. In this type of beam number of unknown forces and the number of equations are the same.

Statically Indeterminate Beams

If the basic equilibrium conditions are not enough to analyse the beam then it is called a statically indeterminate beam. To solve such problems we need to use other conditions like strain energy methods, virtual work methods, etc in combination with basic equilibrium conditions.

Examples of statically indeterminate beams are continuous beams, fixed beams, etc. In this type of beam number of unknown forces and number of equations are not the same.

Beams based on Material

Beams can be made of different materials like timber, concrete, steel or even with a combination of different materials like composite beams. Classification of beams according to the material is steel beams, concrete reinforce beams, timber beams, and composite beams. Each one of the beams is discussed below in detail.

Steel Beams

Steel beams are made of molten steel and are thus high strength, strong, and durable compared to other types of beams.

Steel beams are used in steel roof trusses, ropeways, bridges, workshops, etc.

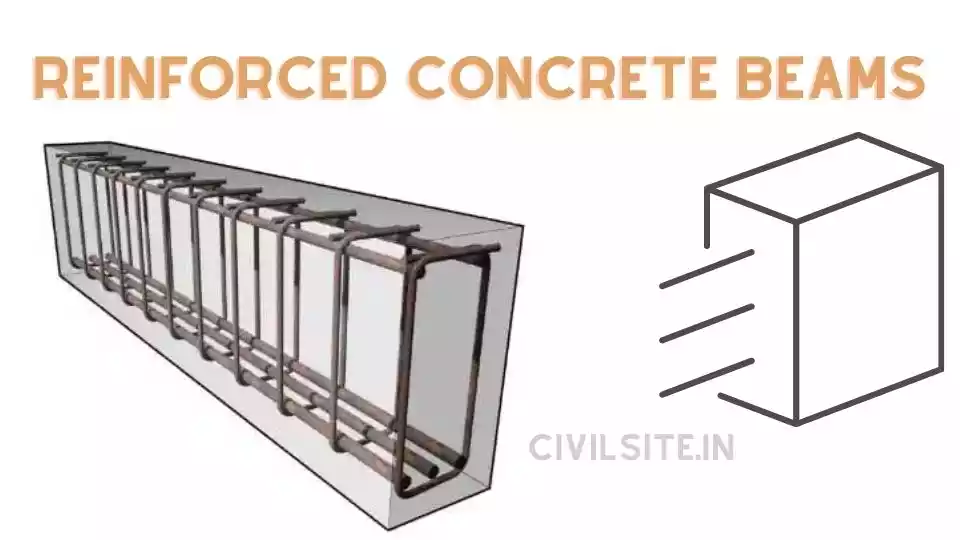

Reinforced Concrete Beams

RCC or Reinforced concrete beams are beams with steel bars and concrete to balance the shear forces, bending moments and torsion occurring in the beams.

Concrete is strong in compression and weak in tension. Thus steel bars are inserted in the concrete beams to counter the tensile forces acting on the beams.

RCC beams support the walls and load coming from the slab and transfer it to the column.

Timber Beams

Timber beams are used in the wooden roof truss and wooden frame structure. Timber is a strong and durable building material that is used since ancient times.

With advancements in the construction industry, new materials are evolving, and thus the use of timber beams is now limited.

Composite Beams

In composite beams, two or more different materials are used together to make a composite beam structure. Composite beams can make use of two materials and the advantages of both the material can be used.

Steel and concrete beams can be used as composite beams. The concrete slab is casted on the steel wide flange and thus tensile strength of steel is used.

Beams based on Construction Methods

The method of construction of beams is different for different types of beams. Based on the construction methods of beam they are classified as cast in situ, precast beams, prestress beams, and lintel beams. Each of the beams is explained in detail with images.

Cast in-situ Concrete Beams

If the beams are cast on the site and cured there, then the beams is called cast-in-situ beams. This type of beam is used if the beams are not of typical size.

Formwork of the required shape and size is fixed and fresh concrete is poured into the forms and vibration to compact the concrete is done using vibratory equipment.

Precast Concrete Beams

Precast concrete beams are casted away from the actual site where it is to be installed and are placed after curing and transportation to the site.

Precast as the name says it is cast and cured before its use. The casting of concrete in precast beams are done in a controlled manner with quality and stringent conditions.

After casting and curing of concrete in a controlled manner the ready-to-use concrete beams are transported to the site for their use.

Prestressed Concrete Beams

Prestressed concrete beams are beams with tension wires that are stressed before the concrete is cast and cured. In prestressed beams, certain required stress is given to the tension wire with the help of hydraulic jacks to keep the concert in the state of compression after it is casted.

Concrete is good in compression and weak in tension thus with the help of high-tension wires we keep concrete always in compression and tension wires take care of tensile forces that can occur in beams.

Lintel Beams

Lintel beams are simple beams that are provided at the top of doors and windows to take the load of the wall above the door and windows.

The main function of the lintel beam is to distribute the load of the walls above doors to the side of the doors, which transfers the load to the beams.

Frequently Asked Questions (FAQ) about Beams

What are the different types of beams?

The following are different types of beams that can be classified:

1. Simply Supported Beams

2. Fixed Beams

3. Over Hanging Beams

4. Double Overhanging Beams

5. Continuous Beams

6. Cantilever Beams

7. Trussed Beams

8. Girdle Beams

9. Straight Beams

10. Curved Beams

11. Tapered Beams

12. Deep Beams

13. Statically Indeterminate Beams

14. Reinforced Concrete Beams

15. Steel Beams

16. Timber Beams

17. Composite Beams

18. Rectangular Beams

19. I Beams

20. T Beams

21. L Beams

22. C Beams

23. Square Beams

24. Cast in-situ Concrete Beams

25. Precast Concrete Beams

26. Prestressed Concrete Beams

27. Lintel Beams

What are the classifications of beams according to the material of the beam?

Classifications of beams according to the material of the beam are as follows:

1. Reinforced Concrete Beams

2. Steel Beams

3. Timber Beams

4. Composite Beams

What are the classifications of beams based on Loads and Supports?

Classifications of beams based on Loads and Supports are as follows:

1. Simply Supported Beams

2. Fixed Beams

3. Over Hanging Beams

4. Double Overhanging Beams

5. Continuous Beams

6. Cantilever Beams

7. Trussed Beams

8. Girdle Beams

What are the classifications of beams based on geometry of beams?

Classifications of beams based on the geometry of beams are as follows:

1. Straight Beams

2. Curved Beams

3. Tapered Beams

4. Deep Beams

What are the classifications of beams based on Equilibrium Conditions of beams?

Classifications of beams based on Equilibrium Conditions of beams are as follows:

1. Statically Determinate Beams

2. Statically Indeterminate Beams

What are the classifications of beams based on Cross-Sectional Shape of beams?

Classifications of beams based on Cross-Sectional Shape of beams are as follows:

1. Rectangular Beams

2. I Beams

3. T Beams

4. L Beams

5. C Beams

6. Square Beams

What are the classifications of beams based on Construction Methods of beams?

Classifications of beams based on Construction Methods of beams are as follows:

1. Cast in-situ Concrete Beams

2. Precast Concrete Beams

3. Prestressed Concrete Beams

4. Lintel Beams

What are the types of support conditions in beams?

Three types of support conditions in beams are as follows:

1. Roller

2. Pinned

3. Fixed

What is the minimum depth of beam?

The minimum depth of an RCC beam is typically 200mm (8 inches), but the actual depth needed depends on factors such as the beam span, load, and design considerations. It’s important to consult with a qualified structural engineer or designer to determine the appropriate depth and size of beams for your project.

What is the maximum size of beam?

There is no standardized maximum size for an RCC beam, as it depends on various factors like design requirements, construction constraints, and material availability. However, in practice, the size of the beam is usually limited by transportation and handling during construction. A qualified structural engineer or designer should be consulted to determine the appropriate beam size based on factors such as span, load-bearing capacity, and design requirements.

1 thought on “Types Of Beams In Construction”