Table of Contents

Among the various finishing techniques available, plaster finishes stand out for their versatility and aesthetic appeal.

In this post, we will go deep into the world of plaster finishes, exploring different types, their applications, and the transformative effects they can have on any space.

What is Plaster Finishes

Plaster finishes have been used for centuries to add character and charm to buildings. Originally derived from natural materials like lime, gypsum, and clay, plaster has evolved into a diverse range of finishes that cater to various aesthetic preferences and functional requirements.

Types of Plaster Finishes

From traditional stucco to luxurious Venetian plaster, each type offers a rich tapestry of possibilities for creating visually stunning and structurally sound surfaces.

Let’s embark on a journey through the world of plaster finishes, discovering the timeless elegance, artistic craftsmanship, and practical advantages that each brings to the realm of architecture and design.

- Traditional Lime Plaster

- Venetian Plaster

- Textured Plaster

- Pebbledash Plaster

- Acoustic Plaster

- Gypsum Plaster

- Clay Plaster

- Polished Plaster

- Tadelakt Plaster

- Stucco Plaster

- Pargeting Plaster

- Drywall Plaster

- Exterior Plaster Finishes

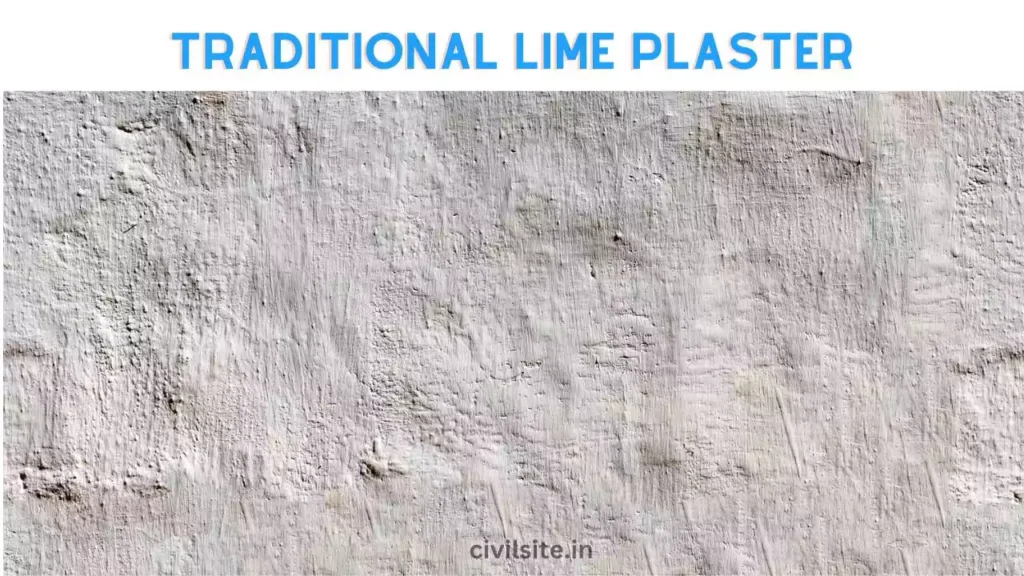

Traditional Lime Plaster

Traditional lime plaster is a building material that has been used for centuries in construction. It is made from a mixture of slaked lime (calcium hydroxide), sand, and water.

Lime plaster is known for its durability, breathability, and versatility, making it a preferred choice for many historical and heritage buildings.

Here are some key characteristics and uses of traditional lime plaster:

Characteristics of Traditional Lime Plaster:

- Breathability: Lime plaster is highly breathable, allowing moisture to evaporate through its surface. This property helps regulate humidity levels within a building and prevents moisture-related issues like mold and decay.

- Flexibility: Lime plaster is more flexible than modern cement-based plasters. This flexibility allows it to expand and contract with the building’s natural movements, reducing the risk of cracks.

- Natural Appearance: Lime plaster provides a soft, matte finish that complements the aesthetics of historic and traditional buildings. It can be left natural or painted with breathable paints.

- Environmentally Friendly: Lime plaster is eco-friendly and sustainable. The production of lime requires less energy than cement, and lime itself is a naturally occurring material.

- Historical Use: Lime plaster has a rich history and has been used in various forms for thousands of years in construction. It is often associated with historic and heritage buildings.

Uses of Traditional Lime Plaster:

- Historic Restoration: Lime plaster is commonly used in the restoration and preservation of historic buildings. Its compatibility with older construction materials and techniques makes it ideal for maintaining the authenticity of heritage structures.

- Heritage Conservation: Lime plaster is preferred for conservation projects aimed at preserving architectural heritage. It allows for the repair and replication of original plaster finishes.

- New Construction: While modern building materials are often used in new construction, some builders and architects choose lime plaster to achieve a traditional or classical aesthetic. It can be used for both interior and exterior applications.

- Sustainable Building: Lime plaster aligns with sustainable building practices due to its low environmental impact. It can be a choice for those seeking to reduce their carbon footprint in construction.

- Artistic Applications: Lime plaster is also used in artistic and decorative applications. Skilled artisans can create intricate plasterwork designs, moldings, and sculptures with lime plaster.

- Fire Resistance: Lime plaster exhibits good fire resistance properties, making it suitable for fireproofing purposes in certain building applications.

It’s important to note that working with traditional lime plaster requires specialized knowledge and skills.

The application and restoration of lime plaster often involve craftsmen and artisans trained in traditional building techniques.

Additionally, lime plaster may not be suitable for all construction projects, so consulting with experts and following local building codes and regulations is essential when considering its use.

Venetian Plaster

Venetian plaster is a luxurious and decorative wall finishing technique that has its origins in Venice, Italy. It is known for its elegant, polished, and marble-like appearance.

Venetian plaster is created by applying multiple layers of a special plaster material to walls or ceilings and then polishing it to a smooth and glossy finish.

Here are some key characteristics and details about Venetian plaster:

Characteristics of Venetian Plaster:

- Rich Appearance: Venetian plaster has a rich and lustrous appearance that resembles the look of natural stone, marble, or polished limestone. It adds a sense of opulence and depth to interior spaces.

- Variety of Finishes: Venetian plaster is available in various finishes, including matte, satin, and high-gloss. Each finish creates a different visual effect and can be tailored to suit the desired aesthetic.

- Depth and Texture: The layering technique used in applying Venetian plaster creates depth and texture on the surface. It can be applied to create smooth, undulating, or textured finishes, depending on the desired effect.

- Customizable Colors: Venetian plaster can be tinted to a wide range of colors, allowing for customization to match the interior design or color scheme of a space.

- Durability: When properly applied and sealed, Venetian plaster is a durable and long-lasting finish that can withstand wear and tear. It is also resistant to moisture and can be used in bathrooms and kitchens.

Application of Venetian Plaster:

The application of Venetian plaster involves several steps:

- Preparation: Ensure that the surface to be plastered is clean, dry, and free of any loose or damaged material. A primer or base coat may be applied to create a smooth and even surface.

- Layering: Venetian plaster is applied in multiple thin layers using a trowel. Each layer is allowed to partially dry before the next is applied. The number of layers depends on the desired finish and depth.

- Burnishing: After the final layer, the plaster is polished using a specialized tool, such as a steel trowel or a Venetian plaster spatula. This process compresses the layers and creates the characteristic sheen and depth of Venetian plaster.

- Sealing: To protect the finish and enhance its durability, a sealer or topcoat is applied. This helps to make the surface resistant to moisture and stains.

- Final Buffing: In some cases, a final buffing or polishing step is performed to achieve the desired level of shine.

Venetian plaster is a technique that requires skill and experience to achieve a flawless finish. It is often applied by trained artisans who specialize in decorative plasterwork.

When properly executed, Venetian plaster can transform ordinary walls into stunning focal points in interior design, adding a touch of elegance and sophistication to residential and commercial spaces.

Recommended for you:

- PCC Full Form In Civil Construction

- Checklist for Beam and Column Shuttering

- Minimum and Maximum Reinforcement in Columns

- Checklist for Plastering

- What is Scaffolding? Types of Scaffolding 2023

- Construction Labour Rate List of Civil Work

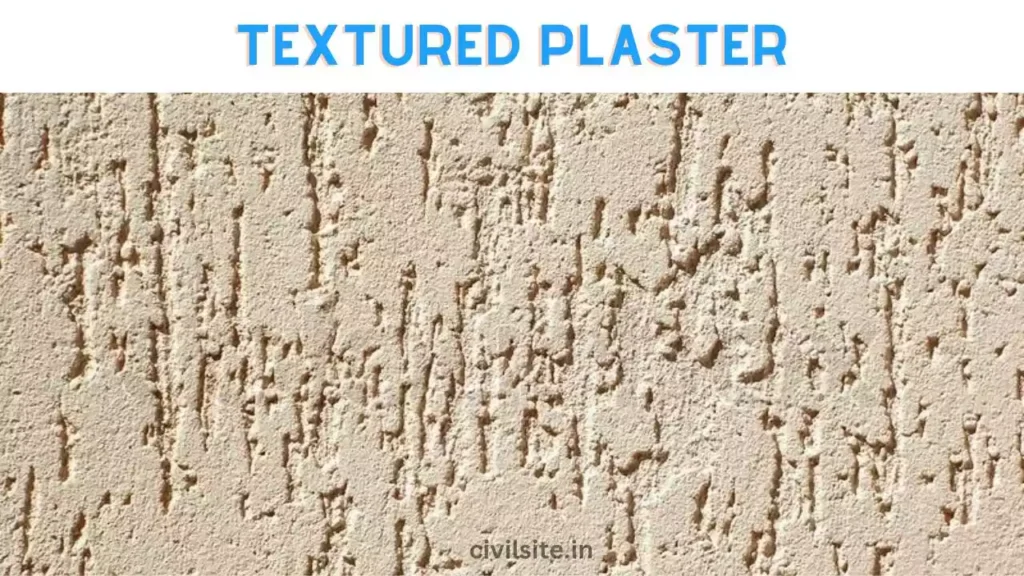

Textured Plaster

Textured plaster is a versatile wall and ceiling finishing technique that adds depth, character, and visual interest to interior surfaces.

Unlike smooth plaster or drywall, textured plaster creates a tactile and decorative surface with various patterns and designs.

This type of finish is popular for its ability to hide imperfections and create unique aesthetics. Here are some key aspects of textured plaster:

Characteristics of Textured Plaster:

- Variety of Textures: Textured plaster offers a wide range of textures and patterns, allowing you to customize the appearance of your walls and ceilings. Common textures include swirls, stippling, sand, popcorn, and more.

- Hide Imperfections: One of the main advantages of textured plaster is its ability to conceal imperfections on the underlying surface. It can mask minor cracks, blemishes, and irregularities in the wall or ceiling.

- Depth and Dimension: Textured plaster adds depth and dimension to interior spaces. The raised patterns and designs create shadows and highlights, enhancing the visual interest of the room.

- Aesthetic Versatility: Textured plaster can be adapted to suit various interior design styles, from traditional to contemporary. It can be further customized by adjusting the texture’s intensity, color, and scale.

- Sound and Acoustic Benefits: Some textured plaster finishes, like popcorn or stipple, can contribute to improved sound absorption and acoustic performance in a room, making it quieter and more comfortable.

- Durable: Textured plaster finishes are durable and can withstand normal wear and tear. They are also relatively easy to clean and maintain.

Application of Textured Plaster:

The application of textured plaster typically involves the following steps:

- Surface Preparation: The surface to be textured should be clean, dry, and free of dust, debris, and loose paint. Any repairs or patching should be completed before applying the texture.

- Texture Application: The texture is applied using specialized tools, such as brushes, rollers, trowels, or spray equipment, depending on the desired texture pattern. The texture material may be mixed with additives like sand or fibers to achieve the desired texture.

- Pattern Creation: The texture material is manipulated to create the desired pattern or texture. Depending on the technique used, this can involve stippling, swirling, or other texturing methods.

- Drying and Curing: The textured surface is allowed to dry and cure according to the manufacturer’s recommendations. This can take anywhere from a few hours to several days, depending on the type and thickness of the texture.

- Painting and Finishing: Once the textured surface is fully dry, it can be painted or finished to achieve the desired color and aesthetics. Many textured plaster finishes are painted to enhance their appearance.

Textured plaster is a versatile choice for interior design and can be applied to walls and ceilings in various settings, including homes, offices, restaurants, and more.

Its ability to add visual interest, hide flaws, and create unique design elements makes it a valuable tool for creating distinctive and appealing interior spaces.

Pebbledash Plaster

Pebbledash plaster is a textured exterior finish used on the walls of buildings, particularly in the United Kingdom and some other regions.

It is known for its distinctive appearance, which features small pebbles or gravel embedded in a cementitious or mortar-based render. Pebbledash is primarily used for its durability and weather-resistant qualities.

Here are some key characteristics and details about pebbledash plaster:

Characteristics of Pebbledash Plaster:

- Textured Surface: The defining characteristic of pebbledash is its textured surface. It consists of small pebbles, gravel, or sometimes crushed stone embedded in the top layer of the plaster.

- Weather Resistance: Pebbledash is highly weather-resistant and can protect the underlying wall structure from rain, wind, and other environmental elements. It is commonly used in coastal areas due to its durability.

- Low Maintenance: One of the advantages of pebbledash is its low maintenance requirements. It doesn’t require frequent painting or sealing and can last for many years with minimal care.

- Aesthetic Variety: While pebbledash is often associated with a rough and rustic appearance, it can be customized to achieve different aesthetics. The type and size of pebbles, as well as the choice of color for the render, can influence the overall look.

- Cost-Effective: Pebbledash is generally considered a cost-effective exterior finish compared to some other cladding options. Its durability and minimal maintenance needs can save on long-term maintenance costs.

Application of Pebbledash Plaster:

The application of pebbledash plaster typically involves the following steps:

- Surface Preparation: The wall surface should be clean and free of debris, dust, and loose material. Any repairs or patching of the underlying structure should be completed before applying the pebbledash.

- Base Coat: A base coat of mortar or render is applied to the wall. This base coat provides a surface for the pebbles to adhere to and creates the desired texture.

- Pebble Application: While the base coat is still wet, small pebbles or gravel are thrown or pressed into the surface. These pebbles become embedded in the mortar, creating the characteristic textured finish. The pebbles are often selected for their size and color to achieve the desired appearance.

- Curing and Drying: The pebbledash finish is left to cure and dry, typically for several days or as specified by the manufacturer. During this time, the mortar hardens, and the pebbles become securely embedded.

- Cleaning and Finishing: After the pebbledash has cured, any loose pebbles or excess mortar are cleaned from the surface. The wall can be left in its natural state or painted with a breathable masonry paint for added protection and aesthetic appeal.

Pebbledash plaster is valued for its practicality and ability to withstand harsh weather conditions.

It is often used on both residential and commercial buildings, particularly in regions where a rugged and weather-resistant exterior is desired.

While it may not be everyone’s preferred aesthetic choice, pebbledash remains a functional and cost-effective option for exterior cladding.

Acoustic Plaster

Acoustic plaster, also known as sound-absorbing or acoustic ceiling plaster, is a specialized type of plaster used to improve the acoustic properties of interior spaces.

It is designed to absorb sound and reduce noise levels within a room, making it an ideal choice for spaces where noise control and sound quality are important considerations.

Here are some key characteristics and details about acoustic plaster:

Characteristics of Acoustic Plaster:

- Sound Absorption: Acoustic plaster is formulated to absorb sound waves rather than reflect them. This helps reduce sound reverberation and echo within a space, resulting in better acoustic comfort.

- Noise Reduction Coefficient (NRC): Acoustic plasters are rated based on their Noise Reduction Coefficient (NRC). The NRC indicates the material’s ability to absorb sound. Higher NRC values signify better sound absorption.

- Customizable Appearance: Acoustic plaster can be customized to achieve different aesthetic effects. It is available in various textures, colors, and finishes, allowing it to blend seamlessly with the overall interior design.

- Durability: Acoustic plaster is durable and can withstand normal wear and tear. It is suitable for both commercial and residential applications.

- Health and Safety: Many acoustic plasters are formulated to meet fire safety and indoor air quality standards. They are typically non-combustible and low in volatile organic compounds (VOCs).

Applications of Acoustic Plaster:

Acoustic plaster is commonly used in a variety of settings where noise control and improved sound quality are important, including:

- Commercial Spaces: Acoustic plaster is often used in offices, conference rooms, hotels, restaurants, and retail spaces to create comfortable and quiet environments for employees and customers.

- Educational Facilities: Schools, colleges, and universities utilize acoustic plaster in classrooms, auditoriums, and lecture halls to enhance speech clarity and reduce noise distractions.

- Cinemas and Theaters: Acoustic plaster can improve the acoustics of cinemas and theaters, ensuring that audiences enjoy optimal sound quality during performances and screenings.

- Healthcare Settings: Hospitals and healthcare facilities may use acoustic plaster in patient rooms, waiting areas, and treatment rooms to create a quieter and more peaceful atmosphere.

- Residential Homes: Homeowners may choose acoustic plaster for home theaters, media rooms, or areas where noise control is a priority.

Installation of Acoustic Plaster:

The installation of acoustic plaster involves the following steps:

- Surface Preparation: Ensure that the ceiling or wall surface is clean, dry, and free of any contaminants. Repair any existing damage or imperfections.

- Application: Acoustic plaster is applied using traditional plastering techniques, such as troweling or spraying. It is carefully applied to achieve the desired texture and finish.

- Drying and Curing: Allow the plaster to dry and cure according to the manufacturer’s recommendations. The drying time may vary depending on the product and environmental conditions.

- Inspection and Testing: After the plaster has fully cured, it may undergo acoustic testing to evaluate its sound absorption performance.

Acoustic plaster is a valuable addition to interior spaces where controlling sound quality and noise levels is essential.

When properly installed, it can contribute to a more comfortable and productive environment for occupants.

Gypsum Plaster

Gypsum plaster, also known as plaster of Paris, is a widely used building material in construction and interior finishing.

It is derived from gypsum, a naturally occurring mineral that is heated, ground, and processed into a fine powder. Gypsum plaster is valued for its versatility, ease of application, and smooth finish.

Here are some key characteristics and details about gypsum plaster:

Characteristics of Gypsum Plaster:

- Ease of Mixing: Gypsum plaster is easy to mix with water, resulting in a creamy consistency that is ideal for application on walls and ceilings.

- Quick Setting: Gypsum plaster sets relatively quickly, which allows for faster construction and finishing. It is known for its rapid setting time, making it a popular choice for professionals.

- Smooth and Even Finish: When properly applied, gypsum plaster produces a smooth, even, and aesthetically pleasing surface that is ready for painting or other finishes.

- Versatility: Gypsum plaster can be used on a variety of substrates, including masonry, concrete, brick, and drywall. It is suitable for both interior and exterior applications.

- Sound Insulation: Gypsum plaster has good sound-insulating properties, making it an effective choice for improving the acoustics of a room.

- Fire Resistance: Gypsum plaster is naturally fire-resistant, which adds an extra layer of safety to buildings. It can help slow down the spread of fire when used as a wall or ceiling finish.

- Durability: Once dry, gypsum plaster is durable and resistant to cracking or shrinking, provided it is applied correctly.

Applications of Gypsum Plaster:

Gypsum plaster finds a wide range of applications in the construction industry, including:

- Wall and Ceiling Finishes: Gypsum plaster is commonly used to finish interior walls and ceilings. It can be applied as a base coat or a finish coat, depending on the desired surface appearance.

- Partition Walls: Gypsum plaster is used in the construction of lightweight partition walls, offering an efficient way to create interior divisions.

- Decorative Molding and Trim: Gypsum plaster is used to create decorative moldings, cornices, and other architectural details. It can be molded into intricate shapes and designs.

- Drywall Jointing: Gypsum plaster is often used for taping and finishing joints in drywall installations.

- Repair and Patching: Gypsum plaster is employed for repairing damaged or cracked walls and ceilings. It can be used for patching holes, imperfections, or small renovations.

Installation of Gypsum Plaster:

The installation of gypsum plaster involves the following steps:

- Surface Preparation: Ensure that the surface to be plastered is clean, dry, and free from dust, grease, and contaminants. Repair any structural or surface defects before applying the plaster.

- Mixing: Gypsum plaster is mixed with clean water according to the manufacturer’s instructions to achieve the desired consistency.

- Application: Apply the plaster evenly to the surface using a trowel or spray equipment. Multiple coats may be necessary, with each coat allowed to dry before applying the next.

- Smoothing and Finishing: After application, the plaster is smoothed and finished to create a uniform surface.

- Drying and Curing: Gypsum plaster dries and cures as it sets. The drying time can vary depending on factors like temperature and humidity.

- Surface Treatment: Depending on the project’s requirements, the surface may be painted, wallpapered, or finished with other materials after the gypsum plaster has fully dried and cured.

Gypsum plaster is a versatile and widely used material in construction and interior design. Its ease of application, quick setting, and smooth finish make it a favored choice for achieving high-quality wall and ceiling surfaces in both residential and commercial buildings.

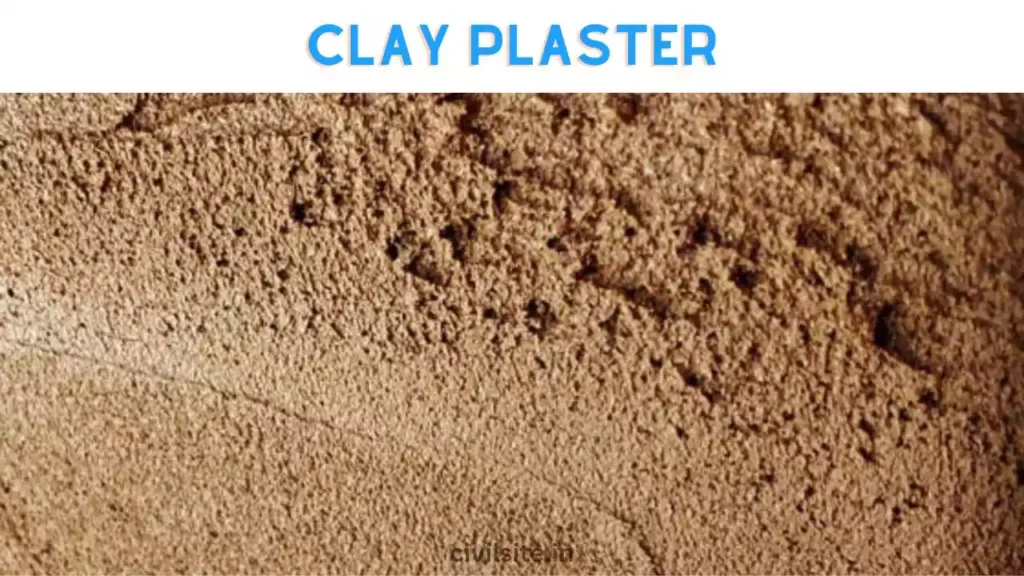

Clay Plaster

Clay plaster, also known as earth plaster or clay-based plaster, is a natural and sustainable building material that has been used for centuries in construction.

It is made from clay, sand, and often straw or other natural fibers, depending on the specific formulation. Clay plaster is valued for its eco-friendliness, breathability, and versatility in creating healthy and aesthetically pleasing interior surfaces.

Here are some key characteristics and details about clay plaster:

Characteristics of Clay Plaster:

- Sustainability: Clay plaster is an eco-friendly material made from abundant and renewable resources. It has a low environmental impact, and its production consumes less energy compared to some other building materials.

- Breathability: Clay plaster is highly breathable and regulates indoor humidity by absorbing and releasing moisture from the air. This natural humidity control can contribute to improved indoor air quality and comfort.

- Non-Toxic: Clay plaster is non-toxic, free from harmful VOCs (Volatile Organic Compounds), and safe for both the environment and human health.

- Versatility: Clay plaster is versatile and can be used for various applications, including walls, ceilings, and even decorative elements. It can be customized with different textures and finishes.

- Aesthetic Appeal: Clay plaster has a warm and natural appearance that adds character to interior spaces. It can be left in its natural state or painted with clay-based paints to achieve different colors and effects.

- Sound Absorption: Clay plaster has good acoustic properties and can help reduce noise levels in rooms, making it suitable for soundproofing applications.

- Thermal Mass: Clay plaster possesses thermal mass properties, which means it can absorb and store heat. This can help regulate indoor temperatures and contribute to energy efficiency.

Applications of Clay Plaster:

Clay plaster can be used in a variety of applications, including:

- Wall Finishes: Clay plaster is commonly used to finish interior walls, creating a unique and visually appealing surface.

- Ceilings: It can also be applied to ceilings to achieve a natural and breathable finish.

- Decorative Elements: Clay plaster can be molded and sculpted to create decorative elements such as moldings, arches, and relief designs.

- Accent Walls: It is often used to create accent walls that add texture and character to a room.

- Restoration: Clay plaster is suitable for the restoration of historic and heritage buildings, where maintaining the original materials and aesthetics is important.

Installation of Clay Plaster:

The installation of clay plaster typically involves the following steps:

- Surface Preparation: Ensure that the surface to be plastered is clean, dry, and free of dust and contaminants. Repair any structural or surface defects before applying the plaster.

- Mixing: Clay plaster is mixed with water to achieve the desired consistency. The addition of natural fibers, such as straw, may be required for added strength and cohesion.

- Application: Apply the clay plaster evenly to the surface using a trowel or similar tool. Multiple coats may be necessary, with each coat allowed to partially dry before applying the next.

- Finishing: After application, the plaster is typically smoothed and finished to create the desired texture and appearance.

- Drying: Allow the clay plaster to dry and cure fully. The drying time can vary depending on environmental conditions.

- Surface Treatment: Depending on the project’s requirements, the surface may be left natural or treated with clay-based paints or finishes for added color and protection.

Clay plaster is an excellent choice for those seeking sustainable and healthy building materials that promote indoor comfort and well-being.

Its timeless and natural aesthetics make it a popular option for interior design, particularly in settings where a warm and inviting atmosphere is desired.

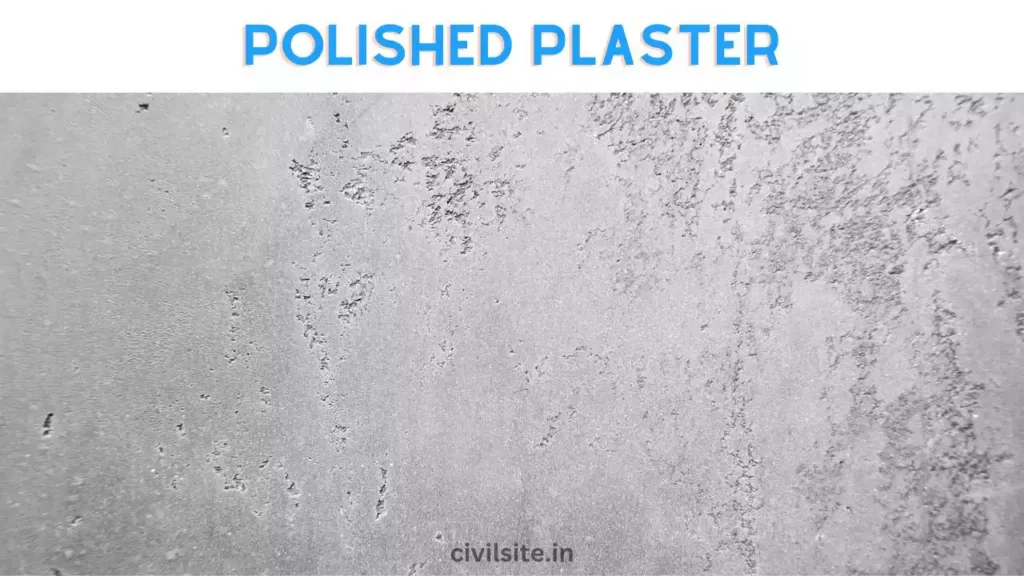

Polished Plaster

Polished plaster, also known as Venetian plaster or polished plaster finish, is a high-end and decorative wall finishing technique that originated in Venice, Italy. It is renowned for its luxurious and glossy appearance, which resembles the look of polished stone or marble.

Polished plaster is created by applying multiple layers of a special plaster material to walls or ceilings and then meticulously polishing it to achieve a smooth and reflective finish.

Here are some key characteristics and details about polished plaster:

Characteristics of Polished Plaster:

- Luxurious Appearance: Polished plaster imparts a luxurious and elegant appearance to interior spaces. It exudes sophistication and depth, resembling the opulence of natural stone surfaces.

- Glossy Finish: The hallmark of polished plaster is its high-gloss finish, which reflects light and creates a visually stunning effect. The depth and shine are achieved through the polishing process.

- Variety of Colors and Textures: Polished plaster is available in a wide range of colors and can be customized to match specific design preferences. It can also be applied in various textures and patterns to create unique visual effects.

- Artistic Possibilities: Skilled artisans can use polished plaster as a canvas for artistic expression. It can be used to create intricate designs, patterns, and murals, adding artistic flair to interior spaces.

- Durability: When properly applied and maintained, polished plaster is a durable finish that can withstand the test of time. It is resistant to chipping, cracking, and fading.

- Warmth and Depth: Polished plaster provides warmth and depth to interior surfaces, making it an ideal choice for creating inviting and captivating environments.

Applications of Polished Plaster:

Polished plaster is used in a variety of interior design settings, including:

- Residential Interiors: Polished plaster is a popular choice for residential spaces, including living rooms, dining rooms, bedrooms, and bathrooms, where it can elevate the overall aesthetic.

- Commercial Spaces: It is frequently used in upscale commercial settings such as hotels, restaurants, boutiques, and offices to create a sophisticated ambiance.

- Feature Walls: Polished plaster is often applied to feature walls or focal points within a room to draw attention and add a touch of luxury.

- Accent Areas: Designers use polished plaster to accentuate architectural details, columns, and ceilings, enhancing the overall design scheme.

- Historic Restoration: Polished plaster is sometimes employed in the restoration of historic and heritage buildings to replicate or preserve the original finishes.

Installation of Polished Plaster:

The installation of polished plaster involves several steps:

- Surface Preparation: Ensure that the surface to be plastered is clean, dry, and free from any imperfections. Repairs and patching should be completed as needed.

- Base Coat: Apply a base coat of plaster or a specific polished plaster base coat material to create a smooth and even surface for the finish coat.

- Application of Finish Coat: The polished plaster finish coat is applied in multiple thin layers using a trowel. Each layer is allowed to partially dry before the next is applied.

- Polishing: After the final layer, the plaster is meticulously polished using specialized tools, such as steel trowels, to achieve the desired shine and smoothness. The polishing process may take several hours or even days.

- Sealing: To protect the finish and enhance its durability, a sealant or topcoat is applied. This step also adds an extra layer of gloss and protection.

- Final Buffing: In some cases, a final buffing or burnishing step is performed to enhance the glossiness of the finish.

Polished plaster is a premium choice for those seeking to create a visually stunning and opulent interior environment.

Due to its intricate application process and the need for skilled craftsmen, it is often considered a high-end finish.

When properly executed, polished plaster can transform ordinary walls and ceilings into works of art, adding timeless elegance and sophistication to any space.

Tadelakt Plaster

Tadelakt plaster is a traditional Moroccan plastering technique that has gained popularity worldwide for its unique characteristics and aesthetic appeal.

It is a waterproof lime plaster finish that is well-known for its smooth, shiny, and polished appearance.

Tadelakt is valued for its ability to create a waterproof seal, making it suitable for wet areas like bathrooms, showers, and even swimming pools.

Here are some key characteristics and details about Tadelakt plaster:

Characteristics of Tadelakt Plaster:

- Waterproof: Tadelakt plaster is inherently waterproof, and it forms a watertight seal when applied correctly. This makes it ideal for wet environments where moisture resistance is crucial.

- Smooth and Shiny Finish: Tadelakt is celebrated for its smooth and shiny finish, which resembles polished marble. The shine is achieved through a unique burnishing and sealing process.

- Natural and Eco-Friendly: Tadelakt is made from natural materials, primarily lime plaster and natural pigments, which makes it an eco-friendly choice for interior finishes.

- Breathable: Despite its waterproof properties, Tadelakt is breathable, allowing moisture vapor to pass through. This helps regulate humidity and reduces the risk of mold or mildew growth.

- Artistic Versatility: Tadelakt can be tinted with natural pigments to achieve various colors and shades. It can also be used to create decorative patterns, designs, or sculpted elements.

- Durable: When properly applied and maintained, Tadelakt is a durable finish that can last for many years without showing signs of wear.

Applications of Tadelakt Plaster:

Tadelakt plaster is commonly used in the following applications:

- Bathrooms and Showers: Tadelakt is a favored choice for bathroom walls, shower enclosures, and even bathtubs due to its waterproof nature and attractive appearance.

- Kitchens: It can be used for kitchen countertops, backsplashes, and sink surrounds where a waterproof and aesthetically pleasing finish is desired.

- Swimming Pools: Tadelakt is used as a pool finish in some regions because of its ability to create a waterproof surface.

- Spa and Hammam Rooms: Tadelakt is traditionally used in Moroccan hammams (steam rooms) and spa areas for its waterproof and luxurious qualities.

- Decorative Elements: Tadelakt can be used to create decorative features such as niches, benches, and intricate designs on walls and ceilings.

Installation of Tadelakt Plaster:

The application of Tadelakt plaster involves several steps:

- Surface Preparation: Ensure that the surface to be plastered is clean, free from dust, and structurally sound. Any necessary repairs or patching should be completed.

- Base Coat: Apply a base coat of lime plaster to the surface and allow it to partially dry. This provides a stable foundation for the Tadelakt finish.

- Tadelakt Application: Apply the Tadelakt plaster in multiple thin layers, allowing each layer to dry before applying the next. The final layer is worked and burnished to create the desired smooth and shiny finish.

- Polishing: After the plaster has dried but is still slightly damp, it is polished with a smooth stone or trowel. This process compacts the surface and enhances the shine.

- Sealing: Apply a natural soap (known as “savon noir”) to the surface, which reacts with the lime to create a waterproof seal. Multiple coats of soap may be applied to achieve the desired level of water resistance.

Tadelakt plaster is a luxurious and distinctive finish that combines functionality with aesthetics.

Its ability to create a waterproof surface, combined with its polished and shiny appearance, makes it a sought-after choice for interior finishes in both traditional and contemporary settings.

Stucco Plaster

Stucco plaster, often simply referred to as “stucco,” is a widely used exterior and interior wall finishing material in construction.

It is composed of a mixture of cement, sand, and water, which is applied in layers to create a durable and decorative finish.

Stucco has a long history and is known for its versatility, durability, and aesthetic appeal.

Here are some key characteristics and details about stucco plaster:

Characteristics of Stucco Plaster:

- Durability: Stucco is a durable and long-lasting material that can withstand various weather conditions, making it suitable for both exterior and interior applications.

- Versatility: Stucco can be applied to a variety of surfaces, including wood, masonry, concrete, and metal. It can also be used on both flat and curved surfaces.

- Aesthetic Variety: Stucco finishes come in a wide range of textures and colors, allowing for customization to match the architectural style and design preferences of a building.

- Fire Resistance: Stucco is naturally fire-resistant and can provide an extra layer of protection to the underlying structure.

- Low Maintenance: Stucco is relatively low maintenance. It requires periodic cleaning and may need occasional repairs, but it generally does not require frequent painting or sealing.

Applications of Stucco Plaster:

Stucco plaster is used in various applications, including:

- Exterior Walls: Stucco is commonly applied to the exterior walls of buildings to provide both protection and an attractive finish. It is used in residential, commercial, and industrial construction.

- Interior Walls: Stucco can be used on interior walls to create textured or decorative finishes. It is particularly popular in some Mediterranean and Southwestern-style interiors.

- Architectural Details: Stucco is often used to create decorative architectural details such as cornices, arches, and columns.

- Ceilings: In some interior designs, stucco is applied to ceilings to add texture and character to a room.

Installation of Stucco Plaster:

The installation of stucco plaster typically involves the following steps:

- Surface Preparation: Ensure that the surface to be stuccoed is clean, free from loose material, and structurally sound. Repair any damage or imperfections.

- Lath Installation: For exterior applications, a metal or wooden lath (mesh) is often installed on the surface to provide a base for the stucco to adhere to. The lath is attached to the building’s framework.

- Base Coat: Apply a base coat of stucco, known as the “scratch coat,” which serves as a bonding layer. It is scored with a scratcher to create a rough surface for the next coat to adhere to.

- Brown Coat: Apply the “brown coat,” which is a thicker layer of stucco that provides additional strength and rigidity.

- Finish Coat: The final layer, known as the “finish coat,” is applied and can be textured or smoothed depending on the desired finish. This is where color and texture customization are incorporated.

- Curing and Drying: Allow the stucco to cure and dry. The drying time can vary depending on factors such as temperature and humidity.

- Optional Sealant or Paint: Depending on the project’s requirements and design preferences, a sealant or paint may be applied to protect and enhance the finish.

Stucco is a versatile and time-tested building material that offers both functional and aesthetic benefits.

Its ability to create a durable and visually appealing finish has made it a popular choice in construction for centuries.

Pargeting Plaster

Pargeting plaster, often simply called “pargeting,” is a decorative plastering technique that involves applying ornamental designs and patterns to the exterior or interior surfaces of buildings.

It is a traditional form of decorative plasterwork that has been used for centuries, primarily in European and English architectural styles.

Pargeting is known for its intricate and artistic designs, which can include motifs, figures, and geometric patterns.

Here are some key characteristics and details about pargeting plaster:

Characteristics of Pargeting Plaster:

- Decorative Artistry: Pargeting is celebrated for its decorative and artistic qualities. Skilled artisans create intricate designs that can range from floral patterns and heraldic symbols to architectural elements like moldings and friezes.

- Historical Significance: Pargeting has a rich historical heritage, particularly in England, where it has been used to adorn the exteriors of Tudor-style and timber-framed buildings. It is often associated with traditional and vernacular architecture.

- Exterior and Interior Applications: Pargeting can be applied to both exterior and interior surfaces. Exterior pargeting is typically seen on the façades of buildings, while interior pargeting may decorate walls, ceilings, or fireplace surrounds.

- Customization: Pargeting designs can be highly customized to reflect the architectural style and cultural influences of a specific region or era. This flexibility allows for a wide range of creative possibilities.

- Durable: When properly maintained, pargeting is a durable finish that can withstand the test of time, though it may require occasional restoration or repairs.

Applications of Pargeting Plaster:

Pargeting plaster is often used in the following applications:

- Exterior Facades: Pargeting is applied to the exterior façades of buildings to create decorative elements that enhance the architectural character and charm of a structure.

- Tudor and Timber-Framed Buildings: It is commonly associated with Tudor-style and timber-framed buildings, where it adds distinctive patterns and ornamentation to the exposed timber beams and panels.

- Fireplace Surrounds: Pargeting is used to decorate the areas surrounding fireplaces, creating a focal point in a room with intricate plasterwork.

- Ceilings and Wall Panels: In some interiors, pargeting is applied to ceilings and wall panels to introduce decorative motifs and patterns.

Installation of Pargeting Plaster:

The installation of pargeting plaster involves a series of steps:

- Surface Preparation: Ensure that the surface to be pargeted is clean, dry, and free from dust, debris, and loose material. Repair any structural or surface defects before applying the plaster.

- Design Creation: Artisans or craftsmen create the design using wet plaster. This step requires considerable skill, as the intricate patterns and details are shaped by hand or with the help of molds or templates.

- Plaster Application: Wet plaster is applied directly to the surface, building up layers to form the desired design. The plaster may contain additives to improve adhesion and workability.

- Modeling and Sculpting: As the plaster sets but remains workable, artisans sculpt and shape the design, adding depth and dimension to the patterns.

- Drying and Curing: The pargeting plaster is left to dry and cure. The drying time can vary depending on environmental conditions.

- Finishing: Once the plaster is fully dry, any rough edges or imperfections are smoothed, and the surface may be painted or sealed to protect and enhance the finish.

Pargeting plaster is a distinctive and historic form of decorative plasterwork that adds character and elegance to buildings. It requires the expertise of skilled craftsmen to achieve intricate and customized designs.

As a result, pargeting remains a valued and cherished aspect of traditional and heritage architecture.

Drywall Plaster

Drywall plaster, also known as joint compound or drywall mud, is a key component in the finishing of drywall or gypsum board surfaces. It plays a crucial role in creating smooth, even, and paintable walls and ceilings.

Drywall plaster is applied to seams, joints, and the fastener heads of gypsum board panels to hide imperfections and create a seamless surface for painting or other wall coverings.

Here are some key characteristics and details about drywall plaster:

Characteristics of Drywall Plaster:

- Variety of Types: Drywall plaster comes in different types, including ready-mixed joint compound, setting-type compound, and texture compounds. Each type has specific properties and uses.

- Ease of Application: Drywall plaster is relatively easy to work with, especially for professionals and DIY enthusiasts. It can be applied with a trowel or drywall knife.

- Quick Drying: Setting-type compounds are known for their rapid drying time, allowing for faster progress during the finishing process.

- Smooth Finish: When properly applied and sanded, drywall plaster creates a smooth and even surface that is ready for paint or other wall finishes.

- Versatility: It can be used for taping and finishing joints, repairing damaged drywall, or creating various textures and decorative effects.

- Low Shrinkage: Modern drywall plasters are formulated to have minimal shrinkage as they dry, which reduces the likelihood of cracks appearing later.

Applications of Drywall Plaster:

Drywall plaster is used in several applications:

- Seams and Joints: The primary purpose of drywall plaster is to cover and finish seams and joints between gypsum board panels. This creates a seamless appearance on walls and ceilings.

- Fastener Heads: Drywall screws and nails used to attach gypsum board panels are covered with plaster to hide them and create a smooth surface.

- Patch and Repair: It is used for patching and repairing damaged areas of drywall, including holes, dents, and cracks.

- Texture Creation: Drywall plaster can be used to create a variety of textures on walls and ceilings, including orange peel, knockdown, and popcorn textures.

Installation of Drywall Plaster:

The installation of drywall plaster typically involves the following steps:

- Surface Preparation: Ensure that the drywall surface is clean, dry, and free from dust, debris, and loose material. Repair any damaged areas before applying the plaster.

- Joint Taping: Apply paper or fiberglass tape to the seams and joints of the drywall panels, embedding it in a layer of wet plaster to create a strong bond.

- First Coat: Apply the first coat of wet plaster over the taped seams and joints. This coat is typically thicker and covers the tape.

- Second Coat: After the first coat has dried, apply a second coat of plaster, feathering it out beyond the joint for a smooth transition.

- Sanding: Once the second coat has dried, sand the surface to remove any imperfections or uneven areas.

- Third Coat (Optional): For particularly smooth finishes, a third thin coat of plaster may be applied and sanded.

- Texture Application (If Desired): If a textured finish is desired, the plaster is applied in the desired texture pattern and then allowed to set before painting.

- Painting or Wall Covering: After the plaster is fully dry and any texture has been applied, the surface is ready for painting or other wall coverings.

Drywall plaster is a fundamental element in the finishing process for gypsum board installations, providing a smooth and uniform appearance to walls and ceilings.

Whether for residential or commercial construction, drywall plaster plays a crucial role in creating appealing and functional interior spaces.

Exterior Plaster Finishes

Exterior plaster finishes, also known as exterior stucco finishes, are a type of protective and decorative coating applied to the exterior surfaces of buildings.

These finishes serve both functional and aesthetic purposes, enhancing the appearance of a structure while providing weather resistance and durability.

Exterior plaster finishes come in various types, each with its own characteristics and design possibilities.

Here are some common types of exterior plaster finishes:

1. Traditional Stucco:

- Traditional stucco is a classic exterior plaster finish made from a mixture of cement, sand, and water.

- It is applied in multiple layers, including a scratch coat, brown coat, and finish coat, each with specific purposes.

- Traditional stucco can be textured or smooth and can be painted in a wide range of colors.

- It is durable, fire-resistant, and weather-resistant, making it suitable for a variety of climates.

2. EIFS (Exterior Insulation and Finish System):

- EIFS is a modern exterior plaster system that includes an insulating layer.

- It consists of a layer of rigid foam insulation board, a base coat with embedded fiberglass mesh for reinforcement, and a finish coat.

- EIFS is known for its energy efficiency and can improve a building’s insulation and thermal performance.

- The finish coat of EIFS can be customized to achieve various textures and colors, providing design flexibility.

3. Acrylic Finish:

- Acrylic finishes are durable and flexible, making them resistant to cracking and peeling.

- They are often used for both new construction and renovations due to their ease of application and repair.

- Acrylic finishes come in a wide range of colors and textures, allowing for creative design possibilities.

- They offer good weather resistance and can resist fading from UV exposure.

4. Lime Render:

- Lime render is a traditional exterior plaster finish made from natural lime, sand, and sometimes additives like hemp or pozzolans.

- It is breathable, which means it allows moisture to pass through, preventing trapped moisture and potential damage to the building.

- Lime render has a natural and textured appearance and can develop a pleasing patina over time.

- It is often used for historic preservation and restoration projects.

5. Venetian Plaster:

- Venetian plaster is typically used for interior applications but can also be applied to exterior feature walls or accents.

- It is a high-end finish that provides a polished and glossy appearance, resembling marble or polished stone.

- Venetian plaster is created by applying multiple thin layers and polishing them to achieve a smooth and reflective surface.

6. Textured Finishes:

- Various textured plaster finishes, such as sand, pebble, or dash finishes, provide a rough and textured appearance to exterior walls.

- These finishes can add visual interest and disguise imperfections in the substrate.

- They are often used in residential and commercial buildings to achieve a rustic or traditional look.

7. Tadelakt:

- Tadelakt, while typically used in wet areas like bathrooms, can be used for specific exterior applications.

- It is a waterproof lime plaster finish known for its smooth, shiny appearance and resistance to water penetration.

The choice of exterior plaster finish depends on factors such as climate, design preferences, budget, and the specific needs of the building.

Proper installation and maintenance are essential to ensure the longevity and performance of exterior plaster finishes, as they provide both protection and aesthetic enhancement to a building’s exterior.

Importance of Plaster Finish

Proper plastering is a crucial aspect of construction and home improvement projects. It involves applying a layer of plaster or mortar mix to walls, ceilings, or other surfaces to create a smooth, even, and durable finish.

The importance of proper plastering cannot be overstated, as it contributes to the structural integrity, aesthetics, and functionality of a building.

Here are several key reasons why proper plastering is essential:

- Structural Integrity: Properly applied plaster can enhance the strength and durability of walls and ceilings. It provides a protective layer that helps prevent cracks, moisture infiltration, and other forms of damage. This structural stability is particularly important in load-bearing walls and areas prone to stress.

- Aesthetic Appeal: Plastering plays a significant role in the visual appeal of a building’s interior and exterior. It creates a smooth and uniform surface that can be painted, textured, or finished in various ways to achieve the desired look. High-quality plasterwork contributes to the overall aesthetics and value of a property.

- Sound Insulation: Plastering can improve the acoustic properties of a room by dampening sound and reducing noise transmission between rooms. This is important for maintaining privacy and creating a comfortable living or working environment.

- Thermal Insulation: Plaster can provide a degree of thermal insulation, helping to regulate indoor temperatures. Properly insulated walls can reduce heating and cooling costs, making a building more energy-efficient.

- Moisture Control: Plaster acts as a barrier against moisture and can help prevent water damage, such as dampness and mold growth. In areas with high humidity or exposure to moisture, like bathrooms and kitchens, effective plastering is vital.

- Smooth Surface for Finishes: Plastering creates a smooth and even base for applying paint, wallpaper, tiles, or other decorative finishes. This ensures that the finishes adhere properly and look their best, enhancing the overall aesthetics of the space.

- Repair and Maintenance: Well-executed plasterwork is easier to repair and maintain over time. It allows for patching and touch-up work without compromising the integrity of the entire surface.

- Longevity: Properly plastered surfaces tend to have a longer lifespan compared to poorly plastered or untreated surfaces. This can save homeowners or property owners from the expense and inconvenience of frequent repairs.

- Value Addition: A well-plastered property generally commands a higher market value. It adds to the curb appeal and can make a property more attractive to potential buyers or renters.

Proper plastering is essential for the structural stability, aesthetic appeal, and functionality of a building. Whether it’s a new construction project or a renovation, investing in high-quality plasterwork can lead to long-lasting benefits and a more comfortable living or working environment.

Choosing the Right Plaster Finish for Your Space

Selecting the right plaster finish for your space is an important decision that can greatly impact the aesthetics and overall feel of your interior or exterior.

Plaster finishes come in a variety of textures and styles, each offering a unique look and function.

Here are some factors to consider when selecting the right plaster finish for your space:

- Architectural Style: Consider the architectural style of your building. Different plaster finishes complement various architectural designs. For example, a smooth, polished plaster finish may suit a modern or minimalist style, while a textured or rustic finish might be more appropriate for a traditional or Mediterranean-style home.

- Location: Think about where the plaster will be applied. Interior and exterior spaces have different requirements. Exterior plaster finishes should be more durable and weather-resistant, while interior finishes can prioritize aesthetics and texture.

- Functionality: Determine the intended function of the space. High-traffic areas like hallways and entryways may benefit from more durable and easily cleanable plaster finishes, such as a Venetian plaster. In contrast, a bedroom or living room may allow for more decorative and textured finishes.

- Lighting: Consider the lighting conditions in the space. Some plaster finishes can play with light in interesting ways. For example, a polished plaster finish can create a reflective surface that enhances natural light, while textured finishes can create subtle shadows and depth.

- Personal Preference: Your personal taste and style preferences should also play a significant role in your decision. Do you prefer a sleek and modern look, or are you drawn to the charm of a textured, Old World finish? Your preferences should align with the overall design vision for your space.

- Maintenance: Different plaster finishes have varying maintenance requirements. Some may require periodic sealing or touch-ups, while others are low-maintenance. Consider how much time and effort you’re willing to invest in upkeep.

- Budget: Plaster finishes come in a range of price points. Keep your budget in mind when making your selection. While some high-end finishes like Venetian plaster can be costly, there are more budget-friendly options available that can still provide an appealing look.

- Climate: If you’re applying plaster finishes outdoors, consider the climate in your region. Plasters that are resistant to moisture and temperature fluctuations may be necessary in areas with extreme weather conditions.

- Samples and Mock-ups: Before making a final decision, request samples or create mock-ups of the plaster finishes you’re considering. This allows you to see how they will look in your specific space and under your lighting conditions.

- Consult a Professional: If you’re unsure about which plaster finish to choose, consult with a professional plasterer or designer. They can offer valuable insights and recommendations based on their expertise.

Selecting the right plaster finish for your space involves a combination of factors, including aesthetics, functionality, personal preference, and budget.

Take your time to explore different options and consider seeking advice from experts to ensure that your chosen plaster finish enhances the beauty and functionality of your space.

Maintenance and Care of Plaster Finishes

Maintaining and caring for plaster finishes is essential to preserve their appearance and integrity over time.

Proper maintenance can help prevent damage and ensure that your plaster surfaces continue to look their best.

Here are some tips on how to maintain and care for plaster finishes:

- Regular Cleaning: Dust and dirt can accumulate on plaster surfaces over time. Regularly dust or gently wipe down your plaster finishes with a soft, dry cloth or a feather duster to keep them clean. Avoid using abrasive materials that could scratch the plaster.

- Avoid Harsh Chemicals: When cleaning plaster, avoid using harsh chemicals or abrasive cleaners. These can damage the finish and cause discoloration. Instead, use a mild, pH-neutral cleaning solution mixed with water. Test it in an inconspicuous area first to ensure it doesn’t harm the plaster.

- Sealing: Depending on the type of plaster finish, it may benefit from periodic sealing. Sealing helps protect the plaster from stains, moisture, and wear. Consult the manufacturer’s recommendations or a professional for guidance on the appropriate sealing products and schedule.

- Repairs and Touch-ups: If you notice any cracks, chips, or damage to the plaster finish, it’s essential to address these issues promptly. Small repairs and touch-ups can prevent more extensive damage from occurring. Consult a professional plasterer for larger repairs.

- Protection from Impact: Plaster finishes can be delicate, especially textured or decorative ones. Take care to avoid impact from sharp objects or heavy items that could cause dents or cracks in the plaster.

- Moisture Control: In areas with high humidity, like bathrooms and kitchens, ensure proper ventilation to reduce the risk of moisture damage. Plaster finishes can be sensitive to moisture and may require special attention in these spaces.

- Avoid Excessive Moisture: When cleaning, avoid saturating the plaster with water. Excessive moisture can lead to staining and damage. Use a damp (not wet) cloth for cleaning.

- Inspect for Cracks: Periodically inspect your plaster finishes for any signs of cracks or damage, especially in high-traffic areas. Address any issues promptly to prevent them from worsening.

- Climate Control: Maintaining stable indoor temperatures and humidity levels can help prolong the life of plaster finishes. Extreme fluctuations in temperature and humidity can lead to plaster deterioration.

- Professional Maintenance: For complex or extensive plaster finishes, consider hiring a professional plasterer for periodic maintenance and inspections. They can identify and address issues that may not be immediately apparent.

- Reapplication or Refinishing: Over time, plaster finishes may naturally wear down or become discolored. Depending on the type of plaster, it may be necessary to reapply or refinish the surface to restore its appearance. Consult with a professional for this process.

Remember that the care and maintenance of plaster finishes can vary depending on the specific type of plaster used, so it’s essential to follow the recommendations provided by the manufacturer or installer.

By taking proper care of your plaster finishes, you can ensure they remain beautiful and functional for years to come.

Timeless Elegance of Plaster Finishes in Modern Architecture

Plaster finishes have a long history in architecture and design, and their timeless elegance continues to be a hallmark of modern architecture.

Despite the advent of new materials and construction techniques, plaster remains a versatile and sought-after choice for adding sophistication and character to contemporary spaces.

Here’s why the timeless elegance of plaster finishes endures in modern architecture:

- Versatility: Plaster can adapt to a wide range of architectural styles, from classic to minimalist to avant-garde. Its versatility allows architects and designers to create diverse aesthetics, making it a suitable choice for both traditional and modern settings.

- Texture and Depth: Plaster offers an unmatched ability to create texture and depth on walls and ceilings. Modern architects often use plaster to add visual interest, whether through intricate molding, sculptural designs, or textured finishes. These techniques bring dimension and character to otherwise plain surfaces.

- Customization: Plaster can be tailored to meet specific design requirements. Architects and designers can work with skilled plaster artisans to create custom finishes, textures, and patterns that align with the vision of a modern space. This level of customization allows for unique and innovative design concepts.

- Seamless Integration: Plaster can seamlessly integrate with various materials and elements used in modern architecture, such as glass, steel, and concrete. Its neutral and adaptable nature allows it to complement other design features without overshadowing them.

- Durability: Modern architecture often emphasizes longevity and sustainability. Plaster finishes, when properly installed and maintained, can withstand the test of time. Their durability makes them a practical choice for modern buildings with a focus on longevity.

- Sound Control: Plaster’s density and thickness provide excellent sound insulation properties. In modern open-plan spaces, where acoustics are crucial, plaster finishes can help create quieter and more comfortable environments.

- Energy Efficiency: Plaster finishes can enhance a building’s energy efficiency. Thermal mass properties in plaster can help regulate temperature fluctuations, reducing the need for excessive heating or cooling in modern, eco-conscious designs.

- Eco-Friendly Options: The availability of natural and eco-friendly plaster materials aligns with the sustainability goals of modern architecture. Lime-based and clay plasters, for example, have minimal environmental impact and can contribute to eco-friendly design practices.

- Timeless Appeal: Plaster finishes have stood the test of time because they exude a timeless elegance. Their classic beauty transcends trends, making them a reliable choice for modern architects who seek a lasting aesthetic.

- Historical Continuity: Incorporating plaster finishes in modern architecture also honors architectural traditions. Many modern architects draw inspiration from historical styles and techniques, and plaster allows them to maintain a connection to the past while creating contemporary designs.

The timeless elegance of plaster finishes in modern architecture lies in their adaptability, versatility, and ability to create visually captivating and enduring spaces.

Plaster continues to be a symbol of sophistication and craftsmanship, making it a valuable asset in the toolbox of contemporary architects and designers striving to create beautiful and functional spaces.

Sustainability and Eco-Friendly Plaster Options

Sustainability and eco-friendliness have become significant considerations in construction and interior design. When it comes to plaster finishes, there are several options and practices that align with these principles. Here are some sustainable and eco-friendly plaster options and practices:

- Natural Plasters: Consider using natural plasters made from renewable and eco-friendly materials. Examples include clay plaster, lime plaster, and earth plaster. These plasters are sourced from natural resources, are biodegradable, and have a low environmental impact. They also offer excellent breathability and moisture regulation.

- Recycled Content: Look for plaster products that incorporate recycled content. Some plaster manufacturers use recycled aggregates or binders in their products, reducing the need for new raw materials and minimizing waste.

- Low-VOC Formulations: Volatile Organic Compounds (VOCs) can release harmful chemicals into the air. Choose plaster finishes that have low or zero VOC formulations. These products have a lower environmental and health impact and contribute to better indoor air quality.

- Local Sourcing: Whenever possible, source plaster materials locally to reduce transportation-related emissions and support local economies. Locally sourced materials also often have a smaller carbon footprint.

- Durability: Opt for plaster finishes that are known for their durability and longevity. Longer-lasting plasters require less frequent replacement or refinishing, reducing overall resource consumption.

- Reclaimed or Salvaged Plaster: Consider using reclaimed or salvaged plaster materials from old buildings or renovation projects. This not only reduces waste but also adds character and history to your space.

- DIY Plaster Mixes: For small projects, you can create your eco-friendly plaster mix using readily available materials like clay, sand, and natural pigments. This allows you to control the ingredients and ensure sustainability.

- Proper Waste Management: When removing or renovating plaster finishes, ensure that waste materials are disposed of properly. Recycling or repurposing old plaster materials can reduce the environmental impact of your project.

- Energy Efficiency: Consider the energy efficiency of your plaster application. Using energy-efficient techniques, such as minimizing waste during application and choosing finishes that require less energy to produce, can contribute to sustainability.

- Sustainable Packaging: Pay attention to the packaging of plaster products. Choose manufacturers that use sustainable and recyclable packaging materials to reduce waste.

- LEED Certification: If you’re working on a commercial or larger-scale project, consider using plaster products that meet LEED (Leadership in Energy and Environmental Design) certification standards. LEED-certified products are rigorously tested for their environmental performance.

- Consult with Experts: When planning a sustainable plaster project, consult with architects, designers, and contractors experienced in sustainable construction practices. They can provide guidance on eco-friendly plaster options and installation methods.

By choosing sustainable and eco-friendly plaster options and following environmentally responsible practices, you can contribute to reducing the environmental impact of your construction or renovation project.

These choices not only benefit the planet but can also lead to healthier indoor spaces and long-term cost savings.

Transforming Commercial Spaces with Unique Plaster Finishes

Transforming commercial spaces with unique plaster finishes is an innovative approach to interior design that can set your business apart and create a memorable and inviting environment.

Plaster finishes offer a wide range of creative possibilities to enhance the aesthetics, functionality, and branding of commercial spaces.

Here are some ways to achieve this transformation:

- Distinctive Textures: Utilize plaster to create one-of-a-kind textures on walls and ceilings. Textured finishes can add depth and visual interest to your commercial space. Consider using techniques like Venetian plaster, which can achieve a smooth, polished look with a subtle sheen, or choose from various textured options for a more rustic or industrial feel.

- Branding and Logos: Incorporate your company’s branding elements, such as logos or slogans, into the plaster finishes. This personalized touch can reinforce your brand identity and create a cohesive and memorable space for clients, customers, and employees.

- Custom Artwork: Commission custom artwork or murals on plastered surfaces. Talented artists can use plaster as their canvas to create unique and visually stunning pieces that reflect your business’s theme or values.

- Color Variations: Experiment with color to make a statement. Plaster can be tinted to match your brand’s colors or to create a specific ambiance within your commercial space. Bold or subtle color choices can dramatically affect the mood and atmosphere.

- Lighting Effects: Plaster finishes can interact with lighting in creative ways. Concealed lighting behind plaster can create a soft, diffused glow or highlight specific design elements. This interplay between plaster and light adds drama and sophistication to your space.

- Architectural Details: Enhance architectural details with plaster molding and trim. Intricate plasterwork can transform plain spaces into elegant and sophisticated areas, reminiscent of classical architectural styles.

- Acoustic Solutions: Plaster can contribute to better acoustics in commercial spaces. Consider using sound-absorbing plaster or incorporating textures and surfaces that help control noise levels, ensuring a comfortable and pleasant environment for patrons and employees.

- Texture Layering: Combine different plaster textures within the same space to create visual contrast and focal points. For example, pair a smooth plaster finish with a more rugged, textured one to add interest and balance.

- Sustainable Materials: Opt for eco-friendly plaster materials that align with your commitment to sustainability. Lime and clay-based plasters, for instance, have minimal environmental impact and can contribute to a green commercial space.

- Maintenance and Durability: Choose plaster finishes that are both aesthetically appealing and durable. Commercial spaces experience high foot traffic, so ensure the plaster can withstand wear and tear and is easy to maintain.

- Consult with Design Professionals: Collaborate with interior designers, architects, and skilled plaster artisans who specialize in commercial projects. Their expertise can help you select the right plaster finishes and techniques to achieve your desired transformation.

Transforming commercial spaces with unique plaster finishes offers an opportunity to create a distinctive and memorable environment that aligns with your brand, enhances the customer experience, and fosters a positive and inviting atmosphere.

Whether you’re renovating a restaurant, retail store, office, or any other commercial establishment, plaster finishes can be a key element in achieving your design vision.

Repairing Damaged Plaster

Over time, plaster finishes may develop cracks or other imperfections. Repairing damaged plaster requires skill and precision to restore the original beauty of the finish.

Repairing damaged plaster is a common maintenance task in older homes and buildings. Plaster can develop cracks, holes, or other imperfections over time due to settling, moisture, or general wear and tear.

Repairing damaged plaster is a relatively straightforward process that can help restore the integrity and appearance of your walls and ceilings.

Here’s a step-by-step guide on how to repair damaged plaster:

Materials You’ll Need:

- Plaster patching compound or plaster of Paris

- Trowel or putty knife

- Sandpaper (medium and fine grit)

- Bucket of water

- Paintbrush

- Primer

- Paint or finishing materials (if necessary)

Step-by-Step Repair Process:

- Prepare the Area:

- Clear the damaged area of any loose or crumbling plaster. Use a putty knife or scraper to gently remove loose bits until you reach solid, stable plaster.

- If there are any cracks in the plaster, use a utility knife to widen them slightly, creating a V-shaped groove. This helps the patching compound adhere better.

- Mix the Patching Compound:

- Follow the manufacturer’s instructions to mix the plaster patching compound or plaster of Paris with water in a clean container. The consistency should be similar to thick paint but not too runny.

- Apply the Patching Compound:

- Use a putty knife or trowel to apply the plaster patching compound to the damaged area. Spread it evenly, pressing it into any cracks or holes.

- Feather the edges of the compound to blend it with the surrounding plaster for a seamless repair. It’s important to work quickly, as plaster can set fast.

- Smooth and Shape the Patch:

- While the patching compound is still wet, use a damp paintbrush or sponge to smooth and shape the compound to match the surrounding texture. If you’re dealing with a textured surface, replicate the texture as closely as possible.

- Allow to Dry:

- Allow the patched area to dry completely. The drying time can vary depending on the thickness of the patch and environmental conditions, but it typically takes several hours to a day.

- Sand and Finish:

- Once the patch is fully dry, use medium-grit sandpaper to smooth the repaired area. Feather the edges again to blend with the surrounding plaster.

- Follow up with fine-grit sandpaper to achieve a smooth finish.

- Prime and Paint (if necessary):

- If the repaired area is visible or if you plan to repaint the entire wall or ceiling, apply a primer to the patched area to ensure even paint adhesion. Let the primer dry.

- Paint the patched area to match the surrounding surface. Feather the paint edges to blend with the existing paint.

- Clean Up:

- Clean your tools and dispose of any waste material properly.

Keep in mind that plaster repair may require multiple coats and sanding to achieve a seamless finish. It’s important to be patient and take your time to ensure a high-quality repair.

If you’re unsure about the repair process or dealing with extensive damage, it’s a good idea to consult with a professional plasterer or contractor for expert assistance.

Conclusion

In the world of interior design and construction, plaster finishes stand as a testament to the harmonious blend of tradition and innovation. With a diverse range of options, plaster finishes offer endless possibilities for transforming spaces into works of art. Whether you seek a rustic charm, a modern sheen, or a touch of opulence, there’s a plaster finish that can bring your vision to life.