Table of Contents

If you want to know about cinder block weight, properties and other important features of cinder block then you will love this post.

To provide you with the most comprehensive insights into the cinder block’s weight, its significance, and its applications, we embark on a journey through the world of construction.

In this article, we will not only demystify the intricacies of cinder block weight but also explore its implications for various construction projects.

The Cinder Block: A Building Block of Excellence

What is Cinder Blocks

Cinder blocks, also known as concrete masonry units (CMUs), are rectangular-shaped building blocks primarily composed of concrete. These blocks, reinforced with steel rods or mesh, exhibit exceptional durability and versatility.

They are available in various sizes and configurations, making them an indispensable choice for construction projects of all scales.

Comparison of Cinder Block With Alternatives

Cinder blocks, also known as concrete blocks, are a common construction material used for various applications.

There are many alternatives of cinder blocks. Let us compare alternative of cinder blocks.

| Aspect | Cinder Blocks | Bricks | Wood | Steel | Concrete | AAC Blocks |

|---|---|---|---|---|---|---|

| Material | Concrete | Clay/Concrete | Wood | Steel | Concrete | Sand/Cement/Aluminum Powder |

| Appearance | Utilitarian | Aesthetic | Warm, Natural | Structural | Utilitarian | Aesthetic, Smooth Surface |

| Insulation | Limited | Better than Cinder Blocks | Requires Additional | Requires Additional | Limited | Good (Cellular Structure) |

| Weight | Heavy | Lighter than Cinder Blocks | Lightest | Lighter | Variable | Significantly Lighter |

| Cost | Moderate | Often More Expensive | Competitive | Often More Expensive | Variable | Often More Expensive |

- Material: Bricks are typically made from clay, shale, or concrete.

- Appearance: Bricks offer a more traditional and aesthetically pleasing look due to their smaller size and smoother surface.

- Insulation: Bricks provide better insulation compared to cinder blocks due to their lower thermal conductivity.

- Weight: Bricks are lighter than cinder blocks, making them easier to handle and transport.

- Cost: Bricks are often more expensive than cinder blocks.

Wood:

- Material: Wood is a natural building material, commonly used for framing and interior applications.

- Appearance: Wood provides a warm and natural appearance but requires regular maintenance.

- Insulation: Wood has natural insulation properties but may require additional insulation for energy efficiency.

- Weight: Wood is much lighter than cinder blocks, making it easier to work with.

- Cost: Wood prices can vary but are often competitive with cinder blocks.

- Material: Steel is primarily used for structural purposes in construction.

- Appearance: Steel is not typically visible in finished buildings, as it is usually concealed within walls or used for framing.

- Insulation: Steel itself is not an insulating material and requires additional insulation for energy efficiency.

- Weight: Steel is much lighter than cinder blocks and is used primarily for structural support.

- Cost: Steel is often more expensive than cinder blocks when used for structural purposes.

- Material: Concrete can be poured on-site or used in precast forms for construction.

- Appearance: Concrete has a utilitarian appearance and is often used for structural elements.

- Insulation: Like cinder blocks, concrete provides limited insulation and may require additional insulation for energy efficiency.

- Weight: Concrete can vary in weight but is generally comparable to cinder blocks.

- Cost: Concrete costs can vary depending on the specific application and mix used.

AAC Blocks (Autoclaved Aerated Concrete):

- Material: AAC blocks are lightweight and made from sand, cement, lime, and aluminum powder.

- Appearance: AAC blocks have a smoother surface and are often used for walls, offering good aesthetics.

- Insulation: AAC blocks provide better insulation compared to cinder blocks due to their cellular structure.

- Weight: AAC blocks are significantly lighter than cinder blocks.

- Cost: AAC blocks are often more expensive than traditional concrete or cinder blocks.

The choice between cinder blocks and other materials depends on factors such as budget, intended use, aesthetics, insulation requirements, and local building codes.

Each material has its advantages and disadvantages, so it’s important to consider your specific project needs when making a decision.

Use of Cinder Blocks

Cinder blocks, also known as concrete blocks, have a wide range of uses in construction and landscaping. Here are some common applications:

- Foundation Walls: Cinder blocks are often used to create the foundation walls of buildings. They provide stability and support for the entire structure.

- Retaining Walls: Cinder blocks are excellent for building retaining walls in landscaping projects. These walls can help prevent soil erosion and create terraced gardens.

- Fencing: Cinder blocks can be stacked to create sturdy fences around properties, offering security and privacy. They can also be used as fence posts.

- Garden Beds: Cinder blocks are popular for constructing raised garden beds. They provide a durable and easily customizable structure for planting.

- Outdoor Kitchens: Cinder blocks are used as a framework for outdoor kitchens and grill islands. They offer a stable base for countertops, appliances, and cooking areas.

- Fire Pits: Stacking cinder blocks can create fire pits for outdoor gatherings. They provide a safe and contained area for fires.

- Utility Sheds: Cinder blocks can be used as the foundation or walls for utility and storage sheds, providing a strong and cost-effective solution.

- Stairs and Steps: Cinder blocks can be used to build outdoor stairs and steps, providing safe access to different levels of a property.

- Sound Barriers: Due to their density, cinder blocks are sometimes used to create sound barriers or walls along highways or near noisy areas.

- Partition Walls: Cinder blocks can be used to create interior partition walls in large spaces like warehouses or industrial buildings.

- Planters and Borders: Cinder blocks can serve as planters or border walls for gardens and landscapes.

- Temporary Structures: Cinder blocks are used to create temporary structures for events, construction sites, or storage needs.

- Art Installations: Some artists and designers use cinder blocks as part of their sculptures or outdoor art installations.

- Storm Shelters: In areas prone to severe weather, cinder blocks may be used to construct storm shelters or safe rooms.

- Outdoor Seating: With the addition of cushions or wooden planks, cinder blocks can be used to create simple outdoor seating arrangements.

Cinder blocks are popular because they are cost-effective, durable, and relatively easy to work with.

However, it’s important to follow construction guidelines and safety precautions when using cinder blocks to ensure the structural integrity and safety of your projects.

Cinder Block Weight: The Crucial Metric

The weight of a cinder block is a critical factor in construction planning and execution. It directly influences structural integrity, load-bearing capacity, and overall project feasibility. To comprehend its significance fully, let’s delve into the specifics of cinder block weight.

Cinder blocks are available in different weight classes, ranging from lightweight to heavyweight. The weight of a standard 8x8x16-inch cinder block typically falls within the range of 28 to 38 pounds. This variation in weight is attributed to differences in composition, design, and manufacturing techniques.

Certainly, here’s an extended table that includes various types of cinder blocks with their approximate weights in both pounds and kilograms:

| Type of Cinder Block | Approximate Weight (per block) in Pounds | Approximate Weight (per block) in Kilograms |

|---|---|---|

| Standard Cinder Blocks | 28 to 38 pounds | 12.7 to 17.2 kilograms |

| Hollow Core Cinder Blocks | 25 to 30 pounds | 11.3 to 13.6 kilograms |

| Solid Cinder Blocks | 38 to 40 pounds | 17.2 to 18.1 kilograms |

| Split-Face Cinder Blocks | 28 to 38 pounds | 12.7 to 17.2 kilograms |

| Interlocking Cinder Blocks | 28 to 38 pounds | 12.7 to 17.2 kilograms |

| Corner Cinder Blocks | 28 to 38 pounds | 12.7 to 17.2 kilograms |

| Bullnose Cinder Blocks | 28 to 38 pounds | 12.7 to 17.2 kilograms |

| Lightweight Cinder Blocks | 20 to 25 pounds | 9.1 to 11.3 kilograms |

| Heavyweight Cinder Blocks | 40 to 45 pounds | 18.1 to 20.4 kilograms |

| Architectural Cinder Blocks | Varies by design | Varies by design |

| Fire-rated Cinder Blocks | Varies by fire resistance rating | Varies by fire resistance rating |

| Custom Cinder Blocks | Varies based on specifications | Varies based on specifications |

Please note that the weights for architectural cinder blocks, fire-rated cinder blocks, and custom cinder blocks can vary significantly based on their specific design, fire resistance rating, or custom specifications. Always refer to the manufacturer’s specifications for precise weight information when working with these specialized types of cinder blocks.

Factors Affecting Cinder Block Weight

1. Composition

Cinder blocks are predominantly made of concrete, cement, aggregates, and sometimes fly ash. The ratio and quality of these components influence the block’s weight. Higher cement content generally results in heavier blocks.

2. Size and Configuration

The size and shape of cinder blocks can vary significantly. Smaller blocks are generally lighter than larger ones. Additionally, blocks with hollow cores are lighter than solid ones.

3. Reinforcement

Some cinder blocks come reinforced with steel rods or mesh. This reinforcement adds to the block’s weight but significantly enhances its load-bearing capacity.

Latest Posts

- Checklist for Plastering Work

- Plumbing Work Checklist

- Home Construction Cost Calculator

- Construction Site Daily Checklist

- Free Concrete Mix Design Calculator

Applications of Cinder Blocks by Weight

Lightweight Cinder Blocks

- Gardening: Lightweight cinder blocks are perfect for creating raised garden beds due to their ease of handling.

- Partition Walls: These blocks are ideal for non-load-bearing interior partition walls.

Medium-Weight Cinder Blocks

- Foundation Walls: Medium-weight blocks strike a balance between ease of handling and load-bearing capacity, making them suitable for residential foundation walls.

- Retaining Walls: They are commonly used in retaining wall construction to withstand moderate pressure.

Heavyweight Cinder Blocks

- Load-Bearing Walls: Heavyweight blocks are essential for load-bearing applications, providing robust structural support.

- Commercial Projects: These blocks are often chosen for commercial buildings where strength and durability are paramount.

Recommended for you

- Brick Size And Types of Bricks | 100+ Standard Size of Masonry Brick In World

- What is Rebar? Types and Grades of Steel Reinforcement

- M20 Concrete Ratio

- Density of Cement, Sand, Aggregate and RCC, PCC Concrete

Cinder Block Weight Calculations

Determining Load Capacity

The weight of cinder blocks directly influences a structure’s load-bearing capacity. To calculate the load capacity of a wall or structure, engineers consider various factors, including the cinder block’s weight, size, and mortar strength.

A simple formula for load capacity calculation is:

[ Load Capacity (in pounds) = Cinder Block Weight (in pounds) × Safety Factor ]

The safety factor typically ranges from 1.5 to 2, depending on the application and local building codes.

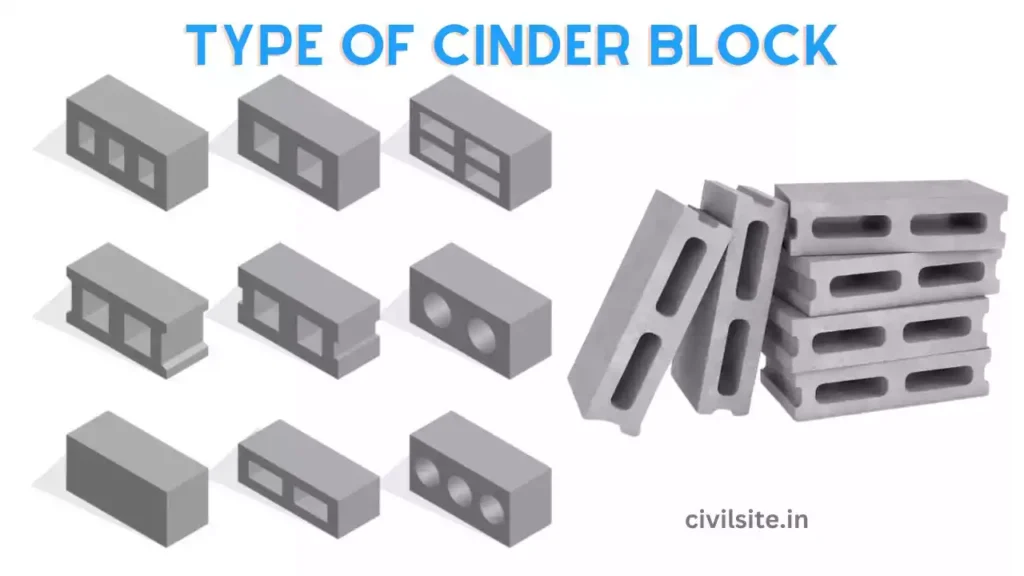

Types of Cinder Blocks

- Standard Cinder Blocks:

- These are the most common and basic type of cinder blocks.

- They come in various sizes but are typically 8x8x16 inches.

- Standard cinder blocks are versatile and used in various construction projects.

- Weight: Approximately 28 to 38 pounds (12.7 to 17.2 kilograms) per block, depending on size and composition.

- Hollow Core Cinder Blocks:

- These cinder blocks have hollow cores, which reduce their weight while maintaining structural integrity.

- They are often used in non-load-bearing walls, making them easier to handle and more cost-effective.

- Weight: Approximately 25 to 30 pounds (11.3 to 13.6 kilograms) per block, depending on size and composition.

- Solid Cinder Blocks:

- Solid cinder blocks do not have hollow cores.

- They are heavier and provide greater structural strength.

- These blocks are commonly used in load-bearing walls and foundation construction.

- Weight: Approximately 38 to 40 pounds (17.2 to 18.1 kilograms) per block, depending on size and composition.

- Split-Face Cinder Blocks:

- These cinder blocks have a textured, rough surface on one or both sides.

- The textured surface adds aesthetic value and can be left exposed in architectural designs.

- Weight: Similar to standard cinder blocks, approximately 28 to 38 pounds (12.7 to 17.2 kilograms) per block.

- Interlocking Cinder Blocks:

- These blocks have a unique interlocking design that helps in creating stable and sturdy walls without the need for mortar.

- They are often used in retaining wall construction and landscaping projects.

- Weight: Similar to standard cinder blocks, approximately 28 to 38 pounds (12.7 to 17.2 kilograms) per block.

- Corner Cinder Blocks:

- Corner blocks are designed to create clean and sturdy corners in walls.

- They have a 90-degree angle, making them essential for maintaining structural integrity in wall construction.

- Weight: Similar to standard cinder blocks, approximately 28 to 38 pounds (12.7 to 17.2 kilograms) per block.

- Bullnose Cinder Blocks:

- Bullnose blocks have a rounded edge on one or more sides.

- They are commonly used for finishing edges and corners, providing a smooth and rounded appearance.

- Weight: Similar to standard cinder blocks, approximately 28 to 38 pounds (12.7 to 17.2 kilograms) per block.

- Lightweight Cinder Blocks:

- These blocks are made with lightweight aggregates, making them easier to handle.

- They are suitable for non-structural applications such as partition walls and garden projects.

- Weight: Approximately 20 to 25 pounds (9.1 to 11.3 kilograms) per block, depending on size and composition.

- Heavyweight Cinder Blocks:

- Heavyweight cinder blocks contain denser aggregates and are more substantial in weight.

- They are used in load-bearing walls and projects where strength is a primary concern.

- Weight: Approximately 40 to 45 pounds (18.1 to 20.4 kilograms) per block, depending on size and composition.

- Architectural Cinder Blocks:

- These blocks are designed with intricate patterns and designs on their surface.

- They are often chosen for decorative purposes in architectural and landscaping projects.

- Fire-rated Cinder Blocks:

- These cinder blocks are specifically designed to withstand high temperatures and are used in fire-rated walls and structures.

- Custom Cinder Blocks:

- Custom blocks can be manufactured to meet specific project requirements in terms of size, shape, and design.

- They are often used in unique architectural designs.

Understanding the different types of cinder blocks allows builders and architects to select the most suitable option for their specific construction needs, whether it’s for structural strength, aesthetics, or other specialized purposes.

Conclusion

Understanding the intricacies of cinder block weight empowers builders, architects, and engineers to make informed decisions. Whether you are embarking on a DIY project or overseeing a large-scale construction endeavor, the weight of cinder blocks plays a pivotal role in ensuring structural integrity and safety.

As we conclude our journey through the world of cinder blocks, we have unraveled the importance of cinder block weight, its variations, and its applications.

Using with this knowledge, you are better equipped to navigate the complex landscape of construction, making informed choices that contribute to the success of your projects.