Table of Contents

Pipes are important to transport fluid like water, oil and some time gases like hydrogen and cooking gas, etc.

In this post we will firstly discussed different pipes and then go through the respective pipe in detail. Lets start with in detail information on plumbing piping material name list.

Different Pipe Types

There are different types of pipes available in the market. Use of certain pipe is advantageous over the other depending upon situation.

Pipes are used for various purpose in our houses. Water is carried into our homes from plumbing pipe made for carrying fresh water. After use waste water is also carried through pipes.

Let us look at different types of piping material first and then will discuss their benefits and drawbacks over each other.

Types of Pipes are as follows:

- Galvanised Iron (GI) Pipes

- Copper Pipes

- Cast Iron Pipes

- Cross Linked Polyethylene (PEX) Pipes

- Brass Pipe

- Acrylonitrile Butadiene Styrene (ABS) Pipes

- Stainless Steel Pipes

- Concrete Pipes

- Chlorinated Poly Vinyl Chloride (CPVC) Pipes

- Unplasticised Poly Vinyl Chloride (UPVC) Pipes

- SWR PVC Pipe

- Polythylene Pipes

- Polypropylene Pipes

- High Density Poly Ethylene (HDPE) Pipes

- Low Density Poly Ethylene (LDPE) Pipes

- Stoneware Pipes

- Asbestos Cement Pipes

- Lead Pipes

- Vinyl Pipes

Recommended For you: Standard Height Of Plumbing Fixtures detailed information.

Let us look in detail about each pipe and know about different properties of plumbing pipe.

Galvanised Iron (GI) Pipes

GI or Galvanised Iron pipes are in use from long time, due to its strength and durability. GI pipes are used in building plumbing work for carrying water.

Galvanised iron pipes are made up of iron so they get corroded when in contact with water. As GI pipe are used for conveying water it get corroded from inside. Thus drinking water gets contaminated with iron particles.

GI pipes are available in 3 grade, that are light quality, medium quality and heavy quality. Grade of GI pipe is governed by the thickness of the pipe. Grades are also identifiable with the help of colours. For 15mm GI pipe 3 grades thickness are 2mm, 2.5 mm and 3.25 mm respectively.

Due to corrosion of GI pipes, it’s use is declining nowadays. Water flow also get hampered due to lesser inner dia because of internal corrosion. Water can get foul smell and taste due to corrosion.

Properties Of Galvanised Iron Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Galvanised Iron (GI) |

| 2. | Lifespan Of pipe | 30-40 years |

| 3. | Durability Of Pipe | Highly Durable |

| 4. | Hazardous or Non-Hazardous | Hazardous |

| 5. | Corrosion Resistance | Highly Corrosive |

| 6. | Mainly Used For | Water supply |

| 7. | Main Advantage | High strength |

| 8. | Main Drawback | Corrosion |

| 9. | Heat Resistance (Hot Condition) | Up to 140 degree fahrenheit |

| 10. | Is it Suitable For Underground Use | Not suitable |

| 11. | Cost of Pipe | High |

GI pipe grades

GI pipes are available in three grades depending on the thickness of the sheet used in the pipe. The three grades are as follows.

- Light- Class A: The pipe is marked in yellow color for identification.

- Medium- Class B: The pipe is marked in blue color for identification.

- Heavy – Class C . The pipe is marked in red color for identification.

GI pipes are available in 6-meter lengths. The fitting used for GI pipes should be IS No: 1239, Part 2 -1990.

Main Features Of Galvanised Iron pipe

- Galvanised iron pipes can withstand heavy loads and high traffic under extreme conditions.

- Iron is galvanised to prevent corrosion, thus galvanised iron pipes are considerably corrosion-resistant. It gets corroded after its upper coating is damaged.

Application Of Galvanised Iron pipe

- Hot and cold water supply in the bathroom

- Water pump-line for pumping water from underground tank to overhead tank.

- Plumbing systems where heavy load or high strength is required.

Advantages Of Galvanised Iron pipe

- Less maintenance as compared to other piping material.

- Reliable under heavy load due to high strength.

- Durable and low cost in the long run.

- GI pipes don’t need additional painting coats as required in iron pipes.

- Gi pipes can be easily inspected with the naked eye.

- Highly abrasion resistant and withstand harsh weather conditions.

- GI pipes can easily be transported and used without any damage.

Disadvantages Of Galvanised Iron pipe

- If zinc coating is damaged then iron get rusted. Thus GI pipes are not resistant to corrosion.

- Galvanised iron pipes can be hazardous due to internal corrosion.

- GI pipes are heavy so workmanship is difficult as compared to other pipes.

Copper Pipes

Copper pipes is one of the first choice for internal plumbing work when budget is not a problem. These pipes can withstand high pressure upto 1000 psi.

Copper is used in bathrooms because copper pipe can handle high temperatures. Thus plumbers prefer copper pipes for hot and cold water applications in bathroom. Water in copper pipe does not freeze in winter as compared to other pipes.

Copper pipes have a high life span of up to 70 years if proper maintenance is done. Thus copper pipes can work best for a family for their lifetime.

Properties Of Copper Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Copper pipes |

| 2. | Lifespan Of pipe | 50-70 ears |

| 3. | Durability Of Pipe | highly durable |

| 4. | Hazardous or Non-Hazardous | non-hazardous |

| 5. | Corrosion Resistance | corrosion resistant |

| 6. | Mainly Used For | Internal Plumbing |

| 7. | Main Advantage | handle high pressure |

| 8. | Main Drawback | expensive |

| 9. | Heat Resistance (Hot Condition) | heat resistant |

| 10. | Is it Suitable For Underground Use | not suitable |

| 11. | Cost of Pipe | Most expensive |

Main Features Of Copper Pipes

- Copper pipes can handle pressure upto 1000 psi.

- Life span of copper pipe is 50-70 years.

- Copper pipe can handle hot and cold temperature easily.

- Copper pipes are light weight

Application Of Copper Pipes

- Copper pipes are mainly used in plumbing of bathrooms for hot water supply and geyser lines.

- Copper Pipe are also used in refrigerant lines in HVAC (Heating Cooling and Air-Conditioning) systems.

Advantages Of Copper Pipes

- Copper pipes are the safest metallic pipes and it does not contaminate water.

- Copper pipes can be recycled easily.

- It can handle high pressure and high temperature.

- Due to light weight copper pipes are easily handled.

- Copper pipes are less harmful to environment.

- Plumbing copper pipes are fire resistant.

Disadvantages Of Copper Pipes

- Copper pipes are one of the most expensive pipes in the market.

- These pipes can not withstand acidic water.

- Metallic flavor can be felt in copper pipes.

Cast Iron Pipes

Cast Iron pipe are durable and heat resistant, thus CI pipe are widely used for plumbing and drainage lines. Due to their durability and sound reduction properties cast iron pipes were best choice of home owners in 1960’s. But now PVC and ABS pipes have taken their place.

Cast iron pipes can last for 50 to 70 years but due to corrosion it get deteriorated sooner. CI pipe need maintenance after 25 to 30 years.

Properties Of Cast Iron Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Cast Iron Pipe |

| 2. | Lifespan Of pipe | 50 years |

| 3. | Durability Of Pipe | Durable |

| 4. | Hazardous or Non-Hazardous | Hazardous |

| 5. | Corrosion Resistance | corrosive |

| 6. | Mainly Used For | Drainage and waste water |

| 7. | Main Advantage | heat resistant |

| 8. | Main Drawback | corrosive |

| 9. | Heat Resistance (Hot Condition) | Heat resistant |

| 10. | Is it Suitable For Underground Use | suitable for underground use |

| 11. | Cost of Pipe | medium |

Main Features Of Cast Iron Pipes

- Cast Iron pipes are heat resistant.

- CI pipe are highly durable.

- CI pipe is good for sound reduction.

Application Of Cast Iron Pipes

- Cast Iron pipe are mainly used for sewage transportation.

- CI pipes are used for waste water downtake lines in vertical lines because PVC pipes can be physically damaged.

Advantages Of Cast Iron Pipes

- Cast iron pipe are sound proof and do not disturb house owners.

- CI pipes are cost effective pipes.

- Cast iron pipes are durable and high strength pipes.

- CI pipes are heat resistant.

Disadvantages Of Cast Iron Pipes

- Cast Iron pipes get corroded as time passes.

- CI pipe are heavy thus considerable energy is required for installation.

- These pipes get slowed down due to corrosion.

Cross Linked Polyethylene (PEX) Pipes

PEX as commonly know its full form is cross linked polyethylene pipes. PEX pipe is mainly used in plumbing water pipes and also used as insulation in high voltage electrical cables.

Cross-linked polyethylene pipes are used as an alternative to polyvinyl chloride pipes, CPVC pipes and copper pipes in residential houses.

Properties Of Cross Linked Polyethylene (PEX) Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Cross Linked Polyethylene (PEX) Pipes |

| 2. | Lifespan Of pipe | 30 to 50 years |

| 3. | Durability Of Pipe | Not very durable |

| 4. | Hazardous or Non-Hazardous | non hazardous |

| 5. | Corrosion Resistance | corrosion resistant |

| 6. | Mainly Used For | Water supply |

| 7. | Main Advantage | flexibility |

| 8. | Main Drawback | perforated by insects |

| 9. | Heat Resistance (Hot Condition) | Heat resistant by insulation |

| 10. | Is it Suitable For Underground Use | not suitable |

| 11. | Cost of Pipe | Cheaper |

Main Features Of Cross Linked Polyethylene (PEX) Pipes

- Cross Linked Polyethylene (PEX) Pipes are flexible thus they it can be used in any circumstances.

- PEX pipes are made up of high density polyethylene (HDPE) material.

Application Of Cross Linked Polyethylene (PEX) Pipes

- PEX pipes are mainly used in Plumbing water system in residential houses.

- It is also widely used in electrical insulation of high voltage electrical cables.

Advantages Of Cross Linked Polyethylene (PEX) Pipes

- PEX pipes are flexible thus can easily be used in any condition.

- Due to its flexibility water flow is also higher in PEX pipes. Thus water pressure is high with PEX pipes as compared to others.

- It is corrosion resistant and unlike iron pipes they can last longer in corrosive environment.

- PEX pipe are suitable for hot and cold pipes.

- Cost of PEX piping cheaper then its alternative.

Disadvantages Of Cross Linked Polyethylene (PEX) Pipes

- PEX pipes can be damaged and perforated by insects.

- Even though PEX pipes are cheaper it’s fittings are costlier.

- PEX pipes can get deteriorated when exposed to direct sunlight.

Brass Pipes

Brass is a combination of copper and zinc and thus brass is an alloy. Brass is widely used material in plumbing industry. But due to its cost brass pipes are not used.

But most other pipes like CPVC and UPVC pipes where threading and joints can get damaged there brass is used. Thus brass finds great application in our house hold plumbing and water supply.

Properties Of

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Brass Pipes |

| 2. | Lifespan Of pipe | |

| 3. | Durability Of Pipe | durable |

| 4. | Hazardous or Non-Hazardous | non hazardous |

| 5. | Corrosion Resistance | corrosion resistant |

| 6. | Mainly Used For | Plumbing water supply |

| 7. | Main Advantage | withstand high temperature |

| 8. | Main Drawback | oxidation of zinc |

| 9. | Heat Resistance (Hot Condition) | heat resistant |

| 10. | Is it Suitable For Underground Use | suitable |

| 11. | Cost of Pipe | high cost |

Main Features Of Brass Pipes

- Brass pipes consist of 85% copper and 15% Zinc and is produced in different shape and sizes.

- Brass is corrosion resistant and malleable thus best for plumbing piping.

Application Of Brass Pipes

- Brass pipes are typically used for plumbing and water supply lines.

- Apart from plumbing brass pipes is also used for carrying chemicals and flammable gases.

Advantages Of Brass Pipes

- Brass pipes are durable and thus they are long lasting.

- They can withstand high temperature thus brass pipe can be used in hot water application.

- Brass pipes are corrosion resistant.

- Brass is malleable and versatile thus it can fit into any plumbing need.

Disadvantages Of Brass Pipes

- Brass contains zinc and with passage of time zinc gets oxidised into zinc oxide forming white powder. This powder blocks the passage of water and slow down the pressure and speed of water.

- Sometime pin hole leakages are formed in brass pipes.

Acrylonitrile Butadiene Styrene (ABS) Pipes

ABS (Acrylonitrile Butadiene Styrene) Pipes are chemical resistant pipes. ABS pipes have low melting temperature.

Acrylonitrile Butadiene Styrene (ABS) Pipes are normally used as pipes in building and plumbing industry for sewer drainage lines and waster water downtake.

Properties Of Acrylonitrile Butadiene Styrene (ABS) Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Acrylonitrile Butadiene Styrene (ABS) Pipes |

| 2. | Lifespan Of pipe | 60 years |

| 3. | Durability Of Pipe | Durable |

| 4. | Hazardous or Non-Hazardous | non hazardous |

| 5. | Corrosion Resistance | corrosion resistant |

| 6. | Mainly Used For | Sewer and plumbing |

| 7. | Main Advantage | Toughness |

| 8. | Main Drawback | Poor UV resistance |

| 9. | Heat Resistance (Hot Condition) | heat resistant |

| 10. | Is it Suitable For Underground Use | suitable |

| 11. | Cost of Pipe | cheaper |

Main Features Of Acrylonitrile Butadiene Styrene (ABS) Pipes

- ABS pipes are light weight pipes and have high impact strength.

- This pipe can be used in wide range of application with varying temperature.

Application Of Acrylonitrile Butadiene Styrene (ABS) Pipes

- ABS has wide application in industrial instruments like tv cabinets, telephone, vaccum cleaners, shower trays, etc.

- ABS pipes are widely used as an alternative to PVC pipes.

Advantages Of Acrylonitrile Butadiene Styrene (ABS) Pipes

- ABS pipes have high impact strength and durability.

- It is a rigid pipes and thus have high toughness.

- It is suitable for -40ºC to 80ºC at pressures up to 15 bar, thus it can be used in wide application.

- ABS is light weight and non toxic pipe.

Disadvantages Of Acrylonitrile Butadiene Styrene (ABS) Pipes

- Poor resistance towards UV rays.

- ABS pipes are poor when it comes to fatigue resistance.

- ABS pipes are high smoke evolution.

Stainless Steel (SS) Pipes

Stainless Steel (SS) Pipes are widely used to carry water, gas, and any liquid that need to be transported under pressure.

Properties Of Stainless Steel (SS) Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Stainless Steel (SS) Pipes |

| 2. | Lifespan Of pipe | 70 years |

| 3. | Durability Of Pipe | Durable |

| 4. | Hazardous or Non-Hazardous | non hazardous |

| 5. | Corrosion Resistance | corrosion resistant |

| 6. | Mainly Used For | nuclear plant |

| 7. | Main Advantage | Corrosion resistant |

| 8. | Main Drawback | heavy weight |

| 9. | Heat Resistance (Hot Condition) | heat resistant |

| 10. | Is it Suitable For Underground Use | suitable |

| 11. | Cost of Pipe | high |

Main Features Of Stainless Steel (SS) Pipes

- Steel pipe are widely used in oil and gas industry as it is durable, high strength and ductile.

- SS pipes are acid resistant and also corrosion resistant.

Application Of Stainless Steel (SS) Pipes

Stainless Steel (SS) Pipes has wide application in many fields, some of them are mentioned below.

- Nuclear power plant

- Oil and gas

- Underground transport of liquid

Advantages Of Stainless Steel (SS) Pipes

Following are the main advantages of Stainless Steel (SS) Pipes

- SS pipes are corrosion resistant and stainless steel pipes are not affected by acid, alkalis and other chemical attacks.

- Stainless steel pipe can give high strength at high temperature.

- SS pipes are high strength pipes and ductile as well.

Disadvantages Of Stainless Steel (SS) Pipes

- Cost of stainless steel pipe is quite high compared to other alternatives.

- Weight of ss pipe is quite heavy.

Concrete Pipes

Concrete pipes are made up of cement concrete and is mainly used for underground drainage lines. Concrete pipes are precast and laid on site. Thus using precast concrete pipes can is faster then constructing channels at site.

Apart form there heavy bulky size these pipes are easy to install and comes in different shape and sizes.

Properties Of Concrete Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Concrete pipes |

| 2. | Lifespan Of pipe | 100 years |

| 3. | Durability Of Pipe | highly durable |

| 4. | Hazardous or Non-Hazardous | hazardous |

| 5. | Corrosion Resistance | corrosion resistant |

| 6. | Mainly Used For | Drainage |

| 7. | Main Advantage | high strength |

| 8. | Main Drawback | Heavy weight |

| 9. | Heat Resistance (Hot Condition) | resistant |

| 10. | Is it Suitable For Underground Use | highly suitable |

| 11. | Cost of Pipe | average |

Main Features Of Concrete Pipes

- Concrete pipes have high strength and can bear heavy loads.

- Lifespan of concrete pipes are quite high and can last for more then 100 years.

Application Of Concrete Pipes

- Concrete pipes are mainly used for underground waste water sewer and drainage work.

- After internally coating concrete pipes, it can also be used for water distribution lines.

Advantages Of Concrete Pipes

- Concrete pipes have high strength and can withstand heavy loads and are generally used in underground drainage pipes.

- These pipes are locally made so concrete pipes are available for use without much transportation.

- Concrete pipe are economical in the long run.

Disadvantages Of Concrete Pipes

- Weight of concrete pipes is quite high as compared to it’s strength.

- Owing to its weight transportation and installation cost is quite high.

- Concrete pipes are less ductile and also its tensile strength is comparatively low.

- Corrosion in concrete pipes is possible due to sulphate attack of hydrogen sulphide from outside soil water.

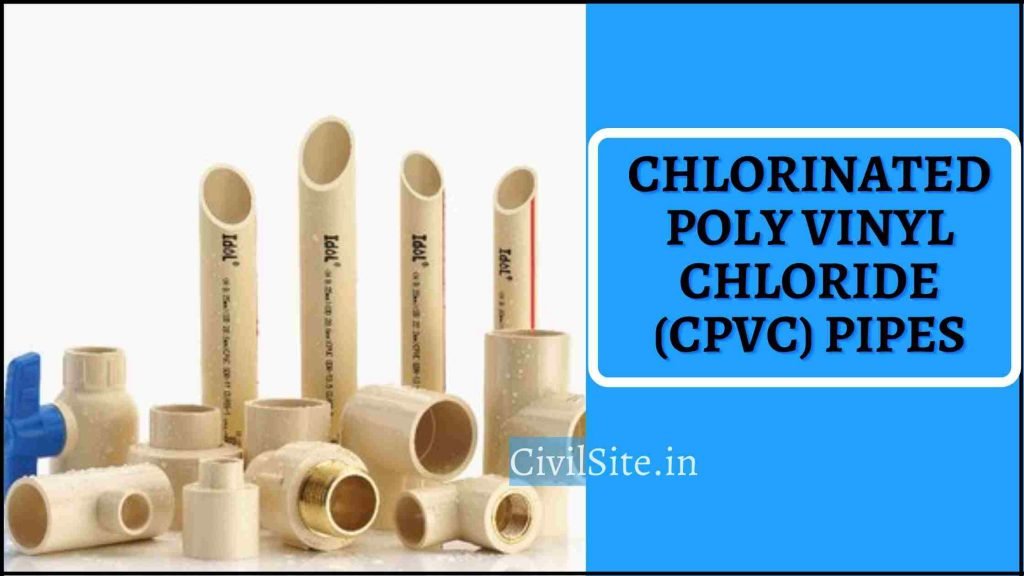

Chlorinated Poly Vinyl Chloride (CPVC) Pipes

Chlorinated Poly Vinyl Chloride (CPVC) Pipes are thermoplastic pipes made by chlorination of polyvinyl chloride. CPVC pipes are more flexible then PVC and can also withstand high temperature. Thus CPVC pipes are preferred choice for hot water supply.

CPVC is ideally used on building plumbing and water supply lines. CPVC pipes can handle as high as 200 degree Fahrenheit temperature easily. It has fire retardant properties.

Properties Of Chlorinated Poly Vinyl Chloride (CPVC) Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Chlorinated Poly Vinyl Chloride (CPVC) Pipes |

| 2. | Lifespan Of pipe | 75 years |

| 3. | Durability Of Pipe | Durable |

| 4. | Hazardous or Non-Hazardous | Non Hazardous |

| 5. | Corrosion Resistance | Corrosion resistant |

| 6. | Mainly Used For | Water supply |

| 7. | Main Advantage | Lower thermal conductivity |

| 8. | Main Drawback | Brittle |

| 9. | Heat Resistance (Hot Condition) | Heat resistant |

| 10. | Is it Suitable For Underground Use | Not suitable |

| 11. | Cost of Pipe | Cheaper |

Main Features Of Chlorinated Poly Vinyl Chloride (CPVC) Pipes

- CPVC pipes are best suited for plumbing bathroom fittings and water supply.

- CPVC pipes are non corrosive in nature.

Application Of Chlorinated Poly Vinyl Chloride (CPVC) Pipes

- CPVC pipes are mainly used for residential building plumbing bathroom fittings.

- Hot water and geyser plumbing work requires CPVC pipes.

Advantages Of Chlorinated Poly Vinyl Chloride (CPVC) Pipes

- CPVC pipes are not corrosive in nature.

- These pipes are easy to install thus time required from CPVC bathroom plumbing is quite low.

Disadvantages Of Chlorinated Poly Vinyl Chloride (CPVC) Pipes

- CPVC pipes are brittle in nature.

- Chlorinated Poly vinyl chloride pipe can not withstand high temperature like copper pipes.

- Thermal coefficient of expansion is low, so CPVC pipes can not be used in areas where temperature varies.

Unplasticised Poly Vinyl Chloride (UPVC) Pipes

UPVC pipes are made up of Poly Vinyl Chloride (PVC) resin and contains no plasticiser in them. Thus they are called as unplasticised Polyvinyl Chloride pipes.

UPVC pipes are chemical resistant pipes. They are also non corrosive in nature thus they are preferred pipes for water supply lines.

Properties Of Unplasticised Poly Vinyl Chloride (UPVC) Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Unplasticised Poly Vinyl Chloride (UPVC) Pipes |

| 2. | Lifespan Of pipe | 70 years |

| 3. | Durability Of Pipe | durable |

| 4. | Hazardous or Non-Hazardous | non toxic |

| 5. | Corrosion Resistance | non corrosive |

| 6. | Mainly Used For | water supply |

| 7. | Main Advantage | corrosion resistant |

| 8. | Main Drawback | poor heat resistance |

| 9. | Heat Resistance (Hot Condition) | poor |

| 10. | Is it Suitable For Underground Use | not suitable |

| 11. | Cost of Pipe | cheaper |

Main Features Of Unplasticised Poly Vinyl Chloride (UPVC) Pipes

- UPVC pipes are corrosion resistant.

- These pipes also don’t react with chemicals.

- UPVC pipes are non hazardous in nature.

Application Of Unplasticised Poly Vinyl Chloride (UPVC) Pipes

- UPVC pipes are widely used for terrace looping for water supply lines and also for cold water plumbing.

- It can also be used for irrigation projects like drip irrigation.

- UPVC pipes are also used in industries piping as they are resistant towards chemical attacks.

Advantages Of Unplasticised Poly Vinyl Chloride (UPVC) Pipes

- UPVC pipes are more flexible then CPVC pipes and also have high tensile strength.

- UPVC pipes are non toxic in nature.

- These pipes are cost effective and easy to install.

- UPVC pipes are non corrosive and leak resistant.

Disadvantages Of Unplasticised Poly Vinyl Chloride (UPVC) Pipes

- UPVC pipes are not heat resistant and work poorly under hot condition.

- UPVC pipe strength is not comparable to metal pipes.

SWR PVC Pipes

SWR stand for soil waste and rain. Thus SWR PVC pipes are used for piping for soil and waste water. SWR PVC pipes are popular choice among plumbers for plumbing work of home.

SWR pipes are resistant towards attacks of bacteria, microorganisms, rodent and other insects.

Properties Of SWR PVC Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | SWR PVC Pipes |

| 2. | Lifespan Of pipe | 50 years |

| 3. | Durability Of Pipe | durable |

| 4. | Hazardous or Non-Hazardous | hazardous |

| 5. | Corrosion Resistance | corrosion resistant |

| 6. | Mainly Used For | Drainage line |

| 7. | Main Advantage | insect resistant |

| 8. | Main Drawback | Low strength |

| 9. | Heat Resistance (Hot Condition) | poor |

| 10. | Is it Suitable For Underground Use | suitable |

| 11. | Cost of Pipe | cheaper |

Application Of SWR PVC Pipes

- SWR PVC pipes are first choice when it comes to soil, waste, rain water downtake lines.

- PVC pipes are also suitable for underground drainage lines.

Advantages Of SWR PVC Pipes

- SWR PVC pipes are chemical resistant and also corrosion resistant. Due to this PVC pipes are widely used for drainage lines.

- PVC pipes are UV resistant.

- SWR PVC pipes are long lasting and provide efficient removal of waste.

Polyethylene Pipes

Properties Of Polyethylene Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Polyethylene Pipes |

| 2. | Lifespan Of pipe | 100+ years |

| 3. | Durability Of Pipe | highly durable |

| 4. | Hazardous or Non-Hazardous | non hazardous |

| 5. | Corrosion Resistance | corrosion resistant |

| 6. | Mainly Used For | drainage |

| 7. | Main Advantage | impact resistant |

| 8. | Main Drawback | expensive |

| 9. | Heat Resistance (Hot Condition) | poor |

| 10. | Is it Suitable For Underground Use | suitable |

| 11. | Cost of Pipe | expensive |

Application Of Polyethylene Pipes

- Urban and rural water supply networks.

- Drainage networks.

- Moving irrigation system.

- Fluid systems and industrial sewage.

Advantages Of Polyethylene Pipes

- PE pipes are low weight, high impact resistance and super flexible.

- Polyethylene pipes are abrasion resistance.

- PE pipes are corrosion resistance.

Disadvantages Of Polyethylene Pipes

- PE pipes are expensive.

- It can not be used in hot water pipes.

Polypropylene Pipes

Properties Of Polypropylene Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Polypropylene Pipes |

| 2. | Lifespan Of pipe | 100 years |

| 3. | Durability Of Pipe | Durable |

| 4. | Hazardous or Non-Hazardous | non hazardous |

| 5. | Corrosion Resistance | corrosion resistant |

| 6. | Mainly Used For | water supply |

| 7. | Main Advantage | chemical resistant |

| 8. | Main Drawback | poor uv protection |

| 9. | Heat Resistance (Hot Condition) | poor |

| 10. | Is it Suitable For Underground Use | not suitable |

| 11. | Cost of Pipe | average |

Application Of Polypropylene Pipes

- Hot and cold potable home water supply piping network.

- PPR pipes are also used for fire sprinkler.

Advantages Of Polypropylene Pipes

- PPR pipes are chemical resistant.

- Polypropylene pipes are corrosion resistant.

- PPR pipes are malleable.

- Polypropylene pipes has high tensile strength, it can withstand 4800 psi.

Disadvantages Of Polypropylene Pipes

- PPR pipes are affected by UV rays.

- Polypropylene pipes have limited use in high temperature environment.

- PPR is highly flammable and poor bonding properties.

High Density Poly Ethylene (HDPE) Pipes

Properties Of High Density Poly Ethylene (HDPE) Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | High Density Poly Ethylene (HDPE) Pipes |

| 2. | Lifespan Of pipe | 50 years |

| 3. | Durability Of Pipe | durable |

| 4. | Hazardous or Non-Hazardous | non hazardous |

| 5. | Corrosion Resistance | corrosion resistant |

| 6. | Mainly Used For | drainage |

| 7. | Main Advantage | light weight |

| 8. | Main Drawback | highly flammable |

| 9. | Heat Resistance (Hot Condition) | poor |

| 10. | Is it Suitable For Underground Use | suitable |

| 11. | Cost of Pipe | expensive |

Application Of High Density Poly Ethylene (HDPE) Pipes

- HDPE pipes are used in water supply systems.

- HDPE pipes are also widely used in drainage systems.

Advantages Of High Density Poly Ethylene (HDPE) Pipes

- HDPE pipes are resistant to corrosion and tuberculation.

- HDPE pipes are resistant towards freeze break.

- High Density Poly Ethylene pipes are light weight and easy for transportation.

Disadvantages Of High Density Poly Ethylene (HDPE) Pipes

- HDPE pipes are highly flammable pipes.

- These pipe are reactive towards acid.

- HDPE pipes are sensitive towards stress cracking.

Low Density Poly Ethylene (LDPE) Pipes

Properties Of Low Density Poly Ethylene (LDPE) Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Low Density Poly Ethylene (LDPE) Pipes |

| 2. | Lifespan Of pipe | 40 years |

| 3. | Durability Of Pipe | durable |

| 4. | Hazardous or Non-Hazardous | hazardous |

| 5. | Corrosion Resistance | corrosion resistant |

| 6. | Mainly Used For | irrigation |

| 7. | Main Advantage | chemical resitant |

| 8. | Main Drawback | high thermal expansion |

| 9. | Heat Resistance (Hot Condition) | poor |

| 10. | Is it Suitable For Underground Use | suitable |

| 11. | Cost of Pipe | average |

Application Of Low Density Poly Ethylene (LDPE) Pipes

- LDPE pipes are used for water and irrigation purpose.

- LDPE pipes are also used for drainage lines.

Advantages Of Low Density Poly Ethylene (LDPE) Pipes

- LDPE pipes are low cost pipes.

- LDPE pipes have good chemical resistance and moisture resistance.

- This pipe can be used for temperature variation from -40 to 90 degree celcius.

Disadvantages Of Low Density Poly Ethylene (LDPE) Pipes

- LDPE pipes have high thermal expansion.

- Poor weathering resistance.

- LDPE pipes are flammable and difficult to bond.

Stoneware Pipes

Properties Of Stoneware Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Stoneware Pipes |

| 2. | Lifespan Of pipe | 70 years |

| 3. | Durability Of Pipe | durable |

| 4. | Hazardous or Non-Hazardous | non hazardous |

| 5. | Corrosion Resistance | resistant |

| 6. | Mainly Used For | drainage |

| 7. | Main Advantage | high strength |

| 8. | Main Drawback | heavy weight |

| 9. | Heat Resistance (Hot Condition) | resistant |

| 10. | Is it Suitable For Underground Use | suitable |

| 11. | Cost of Pipe | average |

Asbestos Cement Pipes

Properties Of Asbestos Cement Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Asbestos Cement Pipes |

| 2. | Lifespan Of pipe | 70 years |

| 3. | Durability Of Pipe | durable |

| 4. | Hazardous or Non-Hazardous | hazardous |

| 5. | Corrosion Resistance | resistant |

| 6. | Mainly Used For | drainage |

| 7. | Main Advantage | sewer and drainage |

| 8. | Main Drawback | brittle |

| 9. | Heat Resistance (Hot Condition) | resistant |

| 10. | Is it Suitable For Underground Use | suitable |

| 11. | Cost of Pipe | cheaper |

Lead Pipes

Properties Of Lead Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Lead Pipes |

| 2. | Lifespan Of pipe | 80 years |

| 3. | Durability Of Pipe | durable |

| 4. | Hazardous or Non-Hazardous | hazardous |

| 5. | Corrosion Resistance | corrosive |

| 6. | Mainly Used For | drainage |

| 7. | Main Advantage | durable |

| 8. | Main Drawback | toxic |

| 9. | Heat Resistance (Hot Condition) | resistant |

| 10. | Is it Suitable For Underground Use | suitable |

| 11. | Cost of Pipe | cheaper |

Vinyl Pipes

Properties Of Vinyl Pipes

| Sr. No. | Description | Properties |

| 1. | Pipe Name | Vinyl Pipes |

| 2. | Lifespan Of pipe | 50 years |

| 3. | Durability Of Pipe | durable |

| 4. | Hazardous or Non-Hazardous | non hazardous |

| 5. | Corrosion Resistance | resistant |

| 6. | Mainly Used For | drainage |

| 7. | Main Advantage | cost effective |

| 8. | Main Drawback | crack easily |

| 9. | Heat Resistance (Hot Condition) | resistant |

| 10. | Is it Suitable For Underground Use | suitable |

| 11. | Cost of Pipe | cheaper |

Properties Comparison for Common Pipe Materials

| Properties | Cast Iron | Copper (Type M) * | CPVC (Schedule 40) | PVC (Schedule 40) | PEX (Class A) |

|---|---|---|---|---|---|

| Cost | N/A | $3.90/ft | $0.83/ft | $0.20/ft | $0.46/ft |

| Pressure Rating @ 73°F | 200 psi | 225 psi | 400 psi | 100 psi | 150 psi |

| Pressure Rating @ 180°F | 200 psi | 120 psi | 100 psi | N/A | 100 psi |

| Max Service Temp | 200 °F | 200 °F | 200 °F | 140°F | 200 °F |

| Softening Point (Vicat Test) | N/A | N/A | 295 °F | 250 °F | 255 °F |

| Melting Point | 2,300 °F | 1,981 °F | 428 °F | 360 °F | 270 °F |

| Thermal Expansion | 0.000006 in/in/°F | 0.000009 in/in/°F | 0.000037 in/in/°F | 0.000028 in/in/°F | 0.000083 in/in/°F |

| Tensile Strength @ 180°F | 25,000 lbs | 34,800 lbs | 8,700 lbs | 6,500 lbs | 1,806 lbs |

| Weight | 12.2 lbs/ft | 0.33 lbs/ft | 0.23 lbs/ft | 0.21 lbs/ft | 0.1 lbs/ft |

| Specific Gravity | 7.89 | 8.96 | 1.54 | 1.4 | 0.94 |

| Corrosion Resitance | Low | Medium | High | High | High |

| Life Expectancy | 20-75 years | 50-75 years | 75-100 years | 75-100 years | 75-100 years |

| Flexibility | None | Slight | Slight | Slight | High |

| Thermal Conductivity | 3.8 Btu in /h ft² °F | 19.2 Btu in /h ft² °F | 1 Btu in /h ft² °F | 1.1 Btu in /h ft² °F | 3.2 Btu in /h ft² °F |

| Specific Heat | 0.11 Btu/lb °F | 0.09 Btu/lb °F | 0.2 Btu/lb °F | 0.25 Btu/lb °F | 0.55 Btu/lb °F |

How to select the best plumbing pipe

Different pipes are used for different purpose, but some time some pipes are best suitable for particular work. Below are the list of pipes that are best for particular work

| Sr. No. | Pipe | Suited For |

| 1. | Galvanised Iron | Grey water |

| 2. | Brass | water tanks and wells |

| 3. | Copper | Hot and cold water |

| 4. | Stainless Steel | Areas subjected to corrosion |

| 5. | Cast Iron | Water distribution system |

| 6. | PEX | Residential and small business |

| 7. | PVC | Cold and Hot potable water |

Classification Of Pipes

Pipes can be classified based on different criteria. Below are some of the criteria based on which pipes can be classified.

Pipes can be classified based on:

- Water supply pipes

- Drainage pipes

- Metallic pipes

- Non-metallic pipes

- Fluid transported

- Pipe Material

Water Supply Pipes

Plumbing pipes are used for safely transporting water from municipal main water supply line into our homes. Pipes are also used to get fresh water into our taps.

Lets us look at different water supply pipes that are widely used.

- Galvanised Iron (GI) Pipes

- Cast Iron (CI) pipes

- UPVC pipes

- CPVC pipes

- Steel pipes

Advantages

- Drinking water can be transported easily using gravity into our homes.

- GI and CI pipes can withstand heavy traffic and load.

- Quality of water is good as compared to trenches and well water.

Disadvantages

- These water supply pipes are long lasting and cheaper in the long run, But high investment is required initially.

- Any damage in the line can cause expensive maintenance cost.

- Due to wear and tear of pipes risk of contamination of water is always there.

- Significant amount of water can be lost due to damage in pipes.

Drainage Pipes

Drainage pipes classified as:

- Concrete drainage pipe

- Asbestos cement pipe

- Clay drainage pipes

- Iron drainage pipes

Metallic Pipes

Pipes that are made from metals are called metallic pipes. Metallic pipes can be further grouped into two groups:

- Pipe made from Ferrous Materials

- Cast Iron (CI) pipes

- Carbon Steel pipes

- Alloy Steel pipes

- Ductile Iron pipes

- DSS pipe

- Pipe made from Non-Ferrous Materials

- Copper pipes

- Aluminum pipes

- Nickel pipes

Non-metallic Pipes

Non Metallic pipes are mostly used in areas where temperature is not high. Mainly non-metallic pipes are used for water transportation and drainage and sewers. Non metallic pipes are as followed:

- ABS pipe

- UPVC pipe

- CPVC pipe

- Cement Pipes

- PPR pipes

- HDPE pipes

Fluid Transported

Pipes are used for different purpose and are used to transport various fluid. Based on the fluid pipes transport, pipes are categorized as:

- Water pipes

- Gas pipes

- Steam pipes

- Oil pipes

- vapour pipes

- hydrogen pipes

Pipe Material

Based on the material of pipe, pipes can be classified as

- Metallic Pipes

- Steel pipe

- Galvanised pipes

- Cast Iron pipe

- Copper pipe

- Brass pipe

- Cement Pipes

- Concrete pipes

- Asbestos Cement pipes

- Plastic Pipes

- UPVC pipe

- CPVC pipe

- SWR PVC

- PPR pipe

- PEX pipe

- HDPE pipe

- LDPE pipe

Plumbing Pipes Use In Our Life

We daily use pipes in our day to day life. Plumbing system is what helps to get hygiene in our house. Let us look at the different pipes that are used in our daily life.

GI or Cast Iron pipes are used to carry water from municipal main water line into our home or building. Water is then store in under ground water tank, from there water is pumped into terrace over head water tank.

UPVC plumbing pipes are used for carrying water from OH tank to our homes. In our houses CPVC pipes are used to get water into our taps.

When we use water it get dirty and waste water is then thrown out of our house into sewer line made up of concrete pipe through SWR PVC pipes.

Frequently Asked Questions on Pipes

What are different types of pipes?

Different types of pipes that are commonly used are as follows:

Galvanised Iron (GI) Pipes

Copper Pipes

Cast Iron Pipes

Cross Linked Polyethylene (PEX) Pipes

Brass Pipe

Acrylonitrile Butadiene Styrene (ABS) Pipes

Stainless Steel Pipes

Concrete Pipes

Chlorinated Poly Vinyl Chloride (CPVC) Pipes

Unplasticised Poly Vinyl Chloride (UPVC) Pipes

SWR PVC Pipe

Polythene Pipes

Polypropylene Pipes

High Density Poly Ethylene (HDPE) Pipes

Low Density Poly Ethylene (LDPE) Pipes

Stoneware Pipes

Asbestos Cement Pipes

Lead Pipes

Vinyl Pipes

What are full form of GI pipe, ABS pipe, UPVC pipe and other pipe?

GI Pipe Full Form = Galvanized Iron Pipes

CPVC Pipe Full Form = Chlorinated Poly-Vinyl Chloride Pipes

UPVC Pipe Full Form = Unplasticized Poly-Vinyl chloride Pipes

CI Pipe Full Form = Cast Iron pipe

SS Pipe Full Form = Stainless Steel

PVC Pipe Full Form = Poly-Vinyl chloride Pipes

HDPE Pipe Full Form = High-Density Polyethylene Pipes

LDPE Pipe Full Form = Low-Density Polyethylene Pipes

ABS Pipe Full Form = Acrylonitrile Butadiene Styrene Pipes

Which Pipes are used for drainage use?

Cast iron

Galvanized steel

ABS

PVC

Galvanized steel

Cast iron

PVC

What are different types of plastic PVC pipes

Unplasticized PVC (UPVC)

Chlorinated PVC (CPVC)

Molecular oriented PVC (PVC-O)

High Impact PVC (PVC-Hi)

What Plumbing Pipes are used in Building Construction?

Rain water Pipe

Waste Water pipe

Soil pipe

Vent pipe

Anti-siphonage pipe

How many types of pipes are there?

There are many pipes available in the market for different purpose and use. According to use and requirement suitable pipes are used. SOme of the pipes are shown below according to use and function.

1. Plastic Pipes for plumbing.

Unplasticized PVC (UPVC)

Chlorinated PVC (CPVC)

Molecular oriented PVC (PVC-O)

High Impact PVC (PVC-Hi)

2. Drainage pipes

Cast iron

Galvanized steel

PVC

Cast iron

PVC

3. Metallic Pipes

Steel pipe

Galvanised pipes

Cast Iron pipe

Copper pipe

Brass pipe

4. Cement Pipes

Concrete pipes

Asbestos Cement pipes

What are Classification of pipes?

Water supply pipes

Drainage pipes

Metallic pipes

Non-metallic pipes

Fluid transported

Pipe Material

What are the 4 most common types of pipe?

Four most common types of pipes are as follows:

1. Galvanised Iron (GI) pipes

2. PVC pipes

3. Copper Pipes

4. PEX pieps

What are 3 types of plumbing pipes?

1. PVC pipes

2. Pex Pipes

3. Copper pipes

What is CPVC pipes plumbing?

CPVC stands for Chlorinated PolyVinyl Chloride pipes. For Complete information on CPVC pipes click here.

How to identify heavy or light GI pipe fittings by colour marking?

1. Light- Class A: The pipe is marked in yellow color for identification

2. Medium- Class B: The pipe is marked in blue color for identification.

3. Heavy – Class C . The pipe is marked in red color for identification.

5 thoughts on “Detailed Information On Pipes | Types Of Pipes | Different Plumbing Pipe and its Uses”